AC Conductivity vs. DC Conductivity: Key Differences and Applications

Quick Summary

- AC and DC conductivity differ in how electricity flows. DC and AC difference lies in direction: DC moves in one steady direction, while AC constantly reverses.

- AC vs DC uses show that AC is ideal for power transmissions, while DC current uses are best for electronics.

- Understanding the key difference between direct current and alternating current helps industries choose the right electrical solutions, especially when designing components like switchgear, control panels, and power distribution units.

Electricity flows through materials in different ways, depending on whether it’s direct current (DC) or alternating current (AC). These two types of electrical conductivity play an important role in how we provide electricity to power our homes, operate electronic devices, and transmit energy over long distances.

While both AC and DC conductivity refer to a material’s ability to conduct electricity, they behave quite differently. Factors such as frequency and material properties greatly influence how electricity moves through a conductor. Understanding these differences is essential for engineers, electricians, and anyone working with electrical systems.

This article explains the key differences in the AC conductivity vs. DC conductivity, along with their uses in real-world applications.

What is DC Conductivity?

DC conductivity means how well a material allows the flow of direct current (DC)—a type of electricity that moves in a straight, unchanging direction. When a voltage is applied in a DC circuit, the current flows at a constant rate without fluctuations.

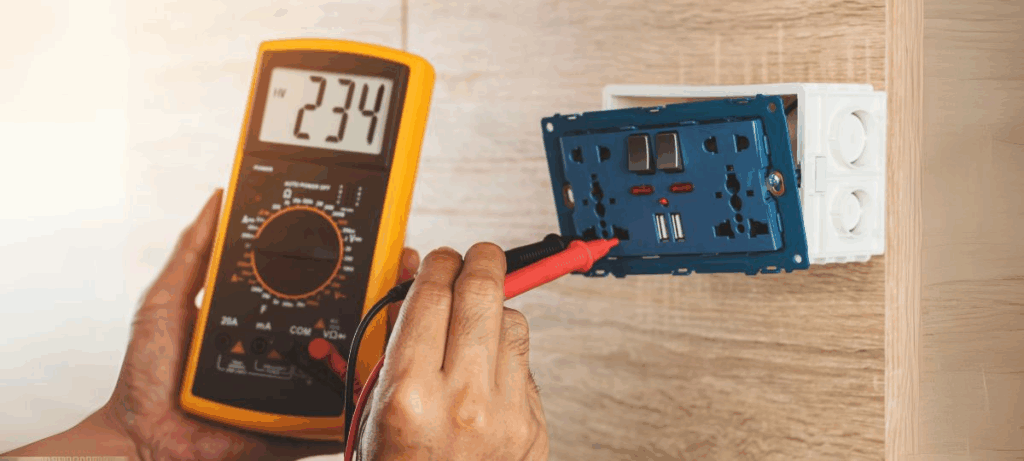

One of the defining characteristics of DC electrical conductivity is its predictable nature. The relationship between voltage, current, and resistance in a DC system follows a simple rule: as long as the resistance stays the same, increasing the voltage will result in a proportional increase in current. This straightforward relationship makes it easy to measure DC voltage with a DC voltmeter and current with a DC ammeter.

Another important factor that affects the DC conductivity is temperature. In metals, conductivity usually decreases as temperature rises because increased heat causes more collisions between electrons, making it harder for them to move freely.

Since DC electricity moves in only one direction, its conductivity is easy to measure and is simple to analyze. why direct current is not used in conductivity measurements is because of the fact that it doesn’t show how materials behave under complex conditions like AC does. It imposes no complications. There are no complications from frequency or alternating phases, so this makes it ideal for applications like batteries, solar panels, and electronic circuits.

What is AC Conductivity?

AC conductivity refers to a material’s ability to conduct alternating current (AC). Here, the flow of electricity constantly changes direction. Unlike DC, which flows in a straight line, AC alternates back and forth in a wave-like pattern. How to measure AC conductivity, this oscillation occurs at different frequencies, and is measured in hertz (Hz), and plays a major role in how electricity behaves in an AC system.

One key aspect of AC conductivity is the presence of reactance, which is resistance that comes from changing electric and magnetic fields. Reactance can cause voltage and current to go out of sync, meaning they don’t always rise and fall together.

Because AC conductivity depends on frequency, it can change depending on how fast the current is oscillating. At lower frequencies, AC behaves similarly to DC. But at higher frequencies, effects such as energy loss come into action.

So, what kind of info does AC conductivity provide? It aids us in understanding how materials perform under varying frequencies. What kind of info does AC conductivity work is useful when designing systems with inductors or capacitors? In essence, what kind of info does AC conductivity? It provides useful insight into material behavior in dynamic conditions.

For those wondering how to measure AC conductivity, or how do you measure conductivity in general, instruments like a conductivity analyzer are used to assess frequency response and impedance. The conductivity measure can reveal variations in phase, loss, and performance based on material type and current frequency.

Key Differences Between AC and DC Conductivity

Who invented AC DC current? The development of these systems is majorly credited to pioneers like Nikola Tesla (AC) and Thomas Edison (DC), whose rivalry shaped the electrical world.

What is difference between alternating current and direct current can be seen across every system we use. In practice, it leads to innovations in smart grids, renewable tech, and automation.

What is DC? DC is direct current, a stable, unidirectional flow of electricity.

What is AC vs DC power? It refers to how power is delivered: AC for homes and transmission; DC for storage and electronics.

While both AC and DC conductivity describe how materials conduct electricity, they differ in several fundamental ways:

Direction of Current Flow

- DC conductivity allows electricity to flow in one constant direction.

- AC conductivity involves a current that reverses direction periodically.

Impact of Frequency

- DC conductivity is not affected by frequency because the current is steady.

- AC conductivity depends on frequency, meaning that higher frequencies introduce additional factors like reactance and the skin effect.

Phase Relationship

- In a DC system, voltage and current stay in synchronization.

- In an AC system, voltage and current may be out of phase, depending on circuit elements like capacitors and inductors.

Resistance vs. Impedance

- In DC circuits, only resistance affects how electricity flows.

- In AC circuits, impedance affects conductivity. This comparison is often termed as dc resistance vs ac resistance.

Conducting Area

- In DC, current flows evenly through the entire cross-section of a conductor.

- In AC, current tends to concentrate near the surface of the conductor at higher frequencies.

Common Uses

- DC conductivity is widely used in batteries, electronic devices, and electrochemical processes.

- AC conductivity is essential for power grids, radio signals, and wireless charging systems.

Applications of DC Conductivity

- Battery-Powered Devices

One major reason why is DC more efficient than AC in these systems is because DC power avoids conversion losses and delivers consistent voltage directly to the device.

Everyday gadgets like smartphones, laptops, and electric vehicles rely on DC power. These represent common applications of DC current. Since DC conductivity doesn’t change with frequency, it ensures consistent power delivery to sensitive electronic components.

- Electrochemical Processes

DC electricity is crucial in electrolysis, where electric current drives chemical reactions, such as splitting water into hydrogen and oxygen. Similarly, industries use DC conductivity in metal plating and corrosion prevention systems like cathodic protection.

- Electronic Circuits

Almost all modern electronics, from microchips to LED lights, depend on DC conductivity. Since DC provides a steady voltage, it’s ideal for powering transistors, diodes, and other semiconductor devices.

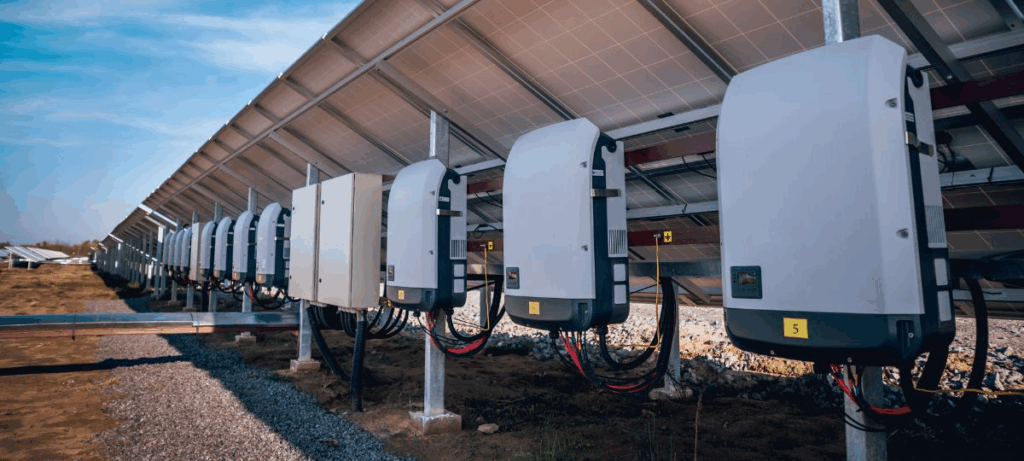

- Renewable Energy Systems

Solar panels generate DC electricity, which is stored in batteries or converted to AC for household use. The direct nature of DC conductivity makes it perfect for solar applications, where energy needs to be stored efficiently.

Applications of AC Conductivity

- Power Transmission and Distribution

The electricity that powers homes and businesses runs on AC because it’s easier to transmit over long distances. This is why AC vs DC current difference is significant in grid design. AC conductivity allows for the use of transformers, which can increase or decrease voltage levels efficiently, reducing energy loss.

- Wireless Charging

AC conductivity plays a crucial role in inductive charging systems, where electrical energy is transferred through magnetic fields. This is how wireless phone chargers and electric vehicle charging pads work.

- Radio and Telecommunications

Radio waves, Wi-Fi, and mobile networks all rely on high-frequency AC conductivity to transmit signals. The ability of AC to oscillate rapidly makes it possible to encode and send information over large distances.

- Medical Applications

AC conductivity is used in medical imaging techniques like electrical impedance tomography (EIT), which helps create internal body scans by measuring how electricity flows through different tissues.

AC/DC Conductivity in Switchgear Design

In the development of electrical switchgear, control panels, and power distribution systems, understanding the difference between AC and DC switchgear is essential. From selecting materials to sizing components and optimizing system efficiency.

Selecting the Right Materials

Both AC and DC installations benefit from using materials with great electrical conductivity, such as copper or silver-coated copper, to reduce energy losses. However, AC systems carry additional challenges. One such example is the skin effect, where alternating current tends to flow along the outer layer of the conductor at higher frequencies. In order to manage this, engineers often opt for laminated busbars or hollow conductors that help in maintaining conductivity while also minimizing resistance.

Sizing Conductors Effectively

Conductors in DC systems must be sized properly to handle constant current loads without excessive heat buildup. For AC systems, additional factors like impedance and inductive reactance are regarded, affecting conductor dimensions and influencing voltage regulation and energy efficiency.

Dealing with the Skin Effect

High-frequency AC applications, common in areas like industrial automation and renewable energy, require particular strategies to counter the skin effect. This often includes the use of Litz wire, silver-plated conductors, or advanced geometries that maintain conductivity while also reducing losses in switchgear configurations.

Conductivity Challenges & GoSwitchgear’s Solutions

Modern electrical systems often face several conductivity-related challenges, including:

- Drops in voltages over long distances

- Buildup of heat due to impedance in AC circuits

- Degradation of conductors in harsh environments

- System inefficiency in mixed AC/DC applications

GoSwitchgear addresses these challenges with:

- Precision-engineered busbars and terminals that help reduce losses and heat

- Advanced insulation and thermal management to increase lifespan and performance

- Material testing and verification to ensure conductivity is consistent under practical and real-world conditions

- Custom-built power distribution units designed for hybrid AC/DC applications, such as renewable energy systems and smart grid integrations

Whether you’re operating in data centers, manufacturing plants, or utility-scale power grids, GoSwitchgear provides proven solutions backed by engineering expertise that you can use.

Explore our Switchgear Solutions

Download Whitepaper: Conductivity in Electrical Systems

Request a Custom Quote

Factors That Influence Conductivity

Several factors affect both AC and DC conductivity, including:

- Temperature:

In metals, higher temperatures usually decrease conductivity, while in semiconductors, conductivity increases with heat.

- Material Composition:

Copper and silver are highly conductive metals, while rubber and glass are strong insulators. Semiconductors fall in between, with their conductivity changing based on external conditions.

- Impurities and Defects:

The presence of contaminants or microscopic defects in a material can disrupt electron flow, reducing conductivity.

- Frequency (for AC Conductivity):

Higher frequencies introduce additional effects, such as the skin effect and dielectric losses, which can change how electricity moves through a material.

Conclusion

Both AC and DC conductivity are essential for powering the modern world. Whether for where is DC current used, such as solar panels, electronics, or AC-based power grids, AC and DC conductivity each play a vital role in making it happen. And our engineered solutions improve reliability and efficiency.

At GoSwitchgear, we supply more than basic components; we engineer customized solutions that account for the conductivity related challenges and demands of your application. Our switchgear, control panels, and distribution units are designed with high-conductivity materials, undergo rigorous testing, and are tailored to fit the specific requirements of AC, DC, or hybrid systems.

At Go Switchgear, we understand the importance of reliable electrical conductivity for both AC and DC applications. Whether you’re working on power transmission, renewable energy systems, or industrial automation, having the correct electrical components can make all the difference.

Go Switchgear offers busbars crafted from high-purity copper, such as ETP (Electrolytic Tough Pitch) and OFHC (Oxygen-Free High Conductivity). These materials not only deliver exceptional electrical and thermal conductivity but also minimize energy loss and heat generation. Leading to an efficient performance. In addition to this, the busbars are available in different shapes to maximize surface area and alleviate the skin effect. Go switchgear also offers robust cable lugs and connectors, and a wide variety of insulating materials are available too. If your requirements are unique, then custom configuration options are available too!

Explore our wide range of high-quality electrical solutions and contact Go Switchgear today to find the perfect products for your needs and ensure safe, efficient power distribution.

Visit our website or reach out to our experts to learn more!

- Request a Quote for Custom Switchgear Solutions

- Download Our Whitepaper on Conductivity in Electrical Systems

- Schedule a Consultation with Our Engineering Team

FAQs

Why is AC used for power transmission instead of DC?

AC is much easier to send over long distances because it works with transformers. This means we can increase or decrease voltage as needed, making it more efficient for delivering electricity to homes and businesses. This highlights the difference between AC and DC in infrastructure.

Where do we use DC conductivity in everyday life?

DC powers batteries, solar panels, and electronic devices like phones and laptops. Since DC provides a steady flow of electricity, it’s perfect for sensitive electronics that need a constant power source.

How does frequency affect AC conductivity?

With AC, the current changes direction at a specific frequency (measured in hertz). The higher the frequency, the more the current tends to concentrate near the surface of the conductor—a phenomenon called the skin effect. This can increase resistance and affect performance in high-frequency applications.

Can we measure AC and DC conductivity in the same way?

Not really. DC conductivity is straightforward—you measure voltage and current to calculate resistance. AC conductivity is trickier because factors like frequency and phase shifts come into play, requiring more advanced measuring tools.

Leave a Reply