Guides to Types of Timer Relay in Control Panels & Automation

Timer relays or time delay relays play a pivotal role in modern automation and control systems. It enables precise timing functions to regulate processes and equipment. In this way, efficiency and functionality are improved. Understanding the different types of timer relay is important for the technicians and engineers because these components are responsible for automation of various operations.

This article provides in-depth details on timer relays used in automation. By understanding how a timer relay contributes to the overall functionality of control panels along with its types, you will have a clear understanding of why selecting the correct type is crucial for ensuring efficiency in automation.

Key Points

- Description of what a timer relay is

- How a timer relay works

- Various types of timer relays used in automation

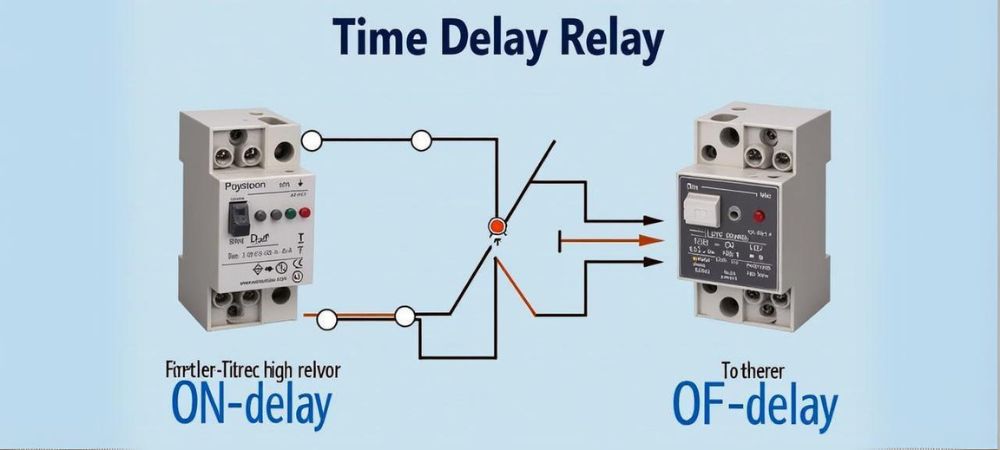

What is a Time Delay Relay?

A timer relay is a device that is used to delay initiation after the command and completion of a specific function. They differ from standard relays in that the standard relay responds immediately to input. In contrast, a timer relay delays the operation of the circuit for a specified period.

The delay provided by the timer relay is used where timing is essential, such as in motor control or automation control. Timer relays work by either delaying the application of power to the circuit (ON-delay) or delaying the removal of power from a circuit (OFF-delay).

This delay ensures that the operation of the equipment works smoothly and in a coordinated manner without any system malfunction.

How Does a Time Delay Relay Work?

A timer relay works on the principle of controlling the flow of current through its contact after a predetermined delay period. A timer relay consists of two main sections:

- Input Section: When voltage is applied to the input, the coil becomes energized. This triggers the timing mechanism by delaying the activation or deactivation of the output contacts.

- Timing Section: This is where the delay is introduced. It can be either Electronic ( Digital relays) or Mechanical ( Electromechanical relays). Once the timing is complete, the relay cuts its contacts to control the connected load.

Depending upon the type of relay, the timing interval can range from milliseconds to hours. Different types of time delay relay are available in the market, some even offering adjustable time settings, which allow the user to fine-tune the delay period according to the requirements.

Types of Time Delay Relays

To control the specific function of control panel accessories, it is necessary to understand various types of timer relay. There are various types of timer relay being discussed below, each designed for a particular function.

1. ON-Delay Timer Relay:

The ON-delay timer relay is most commonly used in control panels. It operates when an input signal is applied, which delays the activation of output contacts. When the input is energized, the timing process begins. After the pre-set delay period, the output contacts switch to their active state.

Applications:

ON-delay relays are commonly used in:

- Motor control

- Sequential start-up of machines

- Powering of equipment to avoid any surges

Example:

Commonly it is used in conveyor belt systems where timer relays ensures that the motor starts in a sequence without overloading the electrical system.

2.OFF-Delay Timer Relay:

The OFF-delay timer delays the deactivation of the devices connected through its output after removing the input signal. When the input signal is removed, the relay maintains the output in its active state for the set delay time before switching it off.

Application:

OFF-delay timer relays are used in equipment that needs to continue running for a specified time after being powered off.

Example: It is mainly used in:

- HVAC systems

- Exhaust fans

- Pumps

- Cooling systems

3.Single-Shot Timer Relay:

A single shot timer relay provides a single timed pulse when powered. This pulse remains active for a predetermined time and does not depend upon how long the input signal remains.

Application:

These are used in the equipment where a momentary action is required with a short pulse activating the mechanism.

Example: It is mostly used in:

- Packaging machinery

- Triggering alarms

- Initiation of a brief signal to the control system.

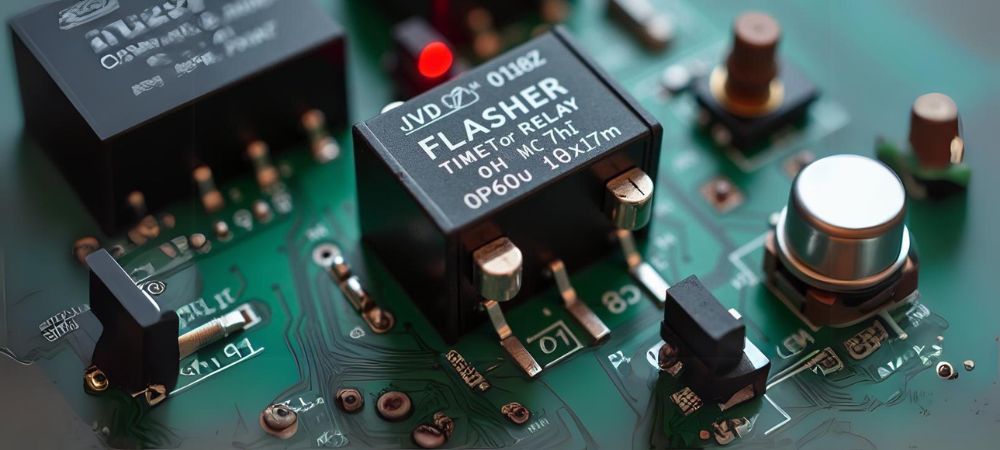

4. Flasher Timer Relay:

It is used to create an intermittent signal by turning the output on and off at regular intervals. This type of relay is very beneficial where periodic signaling is required.

Application:

These are used in the warning systems that require repeated on/off signals.

Example: It is mostly used in:

- Pedestrian crossing lights

- Signal blinkings

- Traffic signals

5. Multi-function Timer Relay:

These types of time delay relays offer multiple timing functions in a single device. This can be ON-delay, OFF-delay, single-shot, or flasher functions. These relays can be programmed to meet specific timing needs.

Application:

Multi-function relays are for systems requiring various timing operations without the need for separate timer relays for each specific function.

Example: It is primarily used in:

- Manufacturing plants

- Complex industrial control systems

- Conveyor belt operations

- Machinery strat-up sequence

6. Interval Timer Relay:

The interval timer relay, once energized, operates for a set time and then returns to its original state. It is not dependent upon the duration of the input signal. In this way, it runs for a specific time and then stops automatically.

Application:

These types of timer relay are employed in the systems where timed operations are crucial.

Example: It is mostly used in:

- Automatic Washing machines

- Batch processing

Automation and Timer Relays in Control Panels:

The world of automation uses Timer relay for controlling various timing operations within a control panel. By using different types of time delay relays, automation systems can achieve precise control processes and reduce operational risks.

Different types of time delay relay contribute to a smoother operation. It also protects the equipment from premature wear.

Synchronizing Operations:

Many industries require the synchronization of operations for automation. Timer relays help in this by ensuring that every component operates in a specific order.

A practical example of this is manufacturing assembly lines. Here ON- delay relays make sure that the machine starts in a correct sequence.

Enhancing Safety:

Timer relays are crucial in areas where safety is required. Different types of time delay relays can be used to control safety mechanisms like emergency shut-off systems.

An OFF-relay ensures that the machine cools down properly before it is disconnected. This ultimately prevents accidents and equipment damage.

Energy efficiency:

Timer relay plays a vital role in energy conservation. It automates the operations like heating, cooling, and lighting in the buildings. Flasher relays can alert workers about equipment malfunction. Interval timers help regulate energy consumption in processes that require intermittent operations.

Conclusion:

Understanding the different types of relay is essential in the realm of control panels and automation. Whether it is an ON-delay relay starting machines in a sequence, an OFF-delay relay making sure equipment cools down, or a multi-function relay managing various tasks, every relay offers a unique function according to the requirements.

The selection of an appropriate time relay depends upon the operational requirements and the overall system architecture. By using these relays, all the automated systems run smoothly and efficiently.

In conclusion, time relay remains an essential component of control panel accessories. With its multiple options, the evolving needs of the modern industry can be fulfilled.

Looking for the best time time relays? Worry no more because Go Switchgear has got you covered. Rush over to their website now to explore a variety of relays that meet your needs.

FAQs:

Q. What is a Timer Relay?

A.Timer relay is a component in control panels used to delay the operations of the electrical circuit for a specified time period.

Q. What is the difference between a Standard relay and a Time relay?

A.Standard relay cuts-off the input to the system immediately. In contrast, a Time relay is designed to delay the operations for a specific time period according to the demand.

Q. What are the applications of a Time relay?

A.Time relay can be used in fields where optimized operation is required, such as traffic signals, automatic washing machines, conveyor belts, safety devices, batch processing, and much more.

Leave a Reply