Revolutionizing Energy Efficiency: A Smart Energy Monitoring System for Triton Frozen Food Manufacturing

Introduction

In a dynamic manufacturing sector of UAE where energy efficiency is paramount, Triton Foods, a leading frozen food manufacturing company in Ajman, UAE, has taken a giant leap towards sustainable operations. Partnering with GoSwitchgear, a pioneer in energy solutions, Triton Foods has successfully implemented an advanced energy monitoring system to optimize consumption and reduce costs.

The Challenge

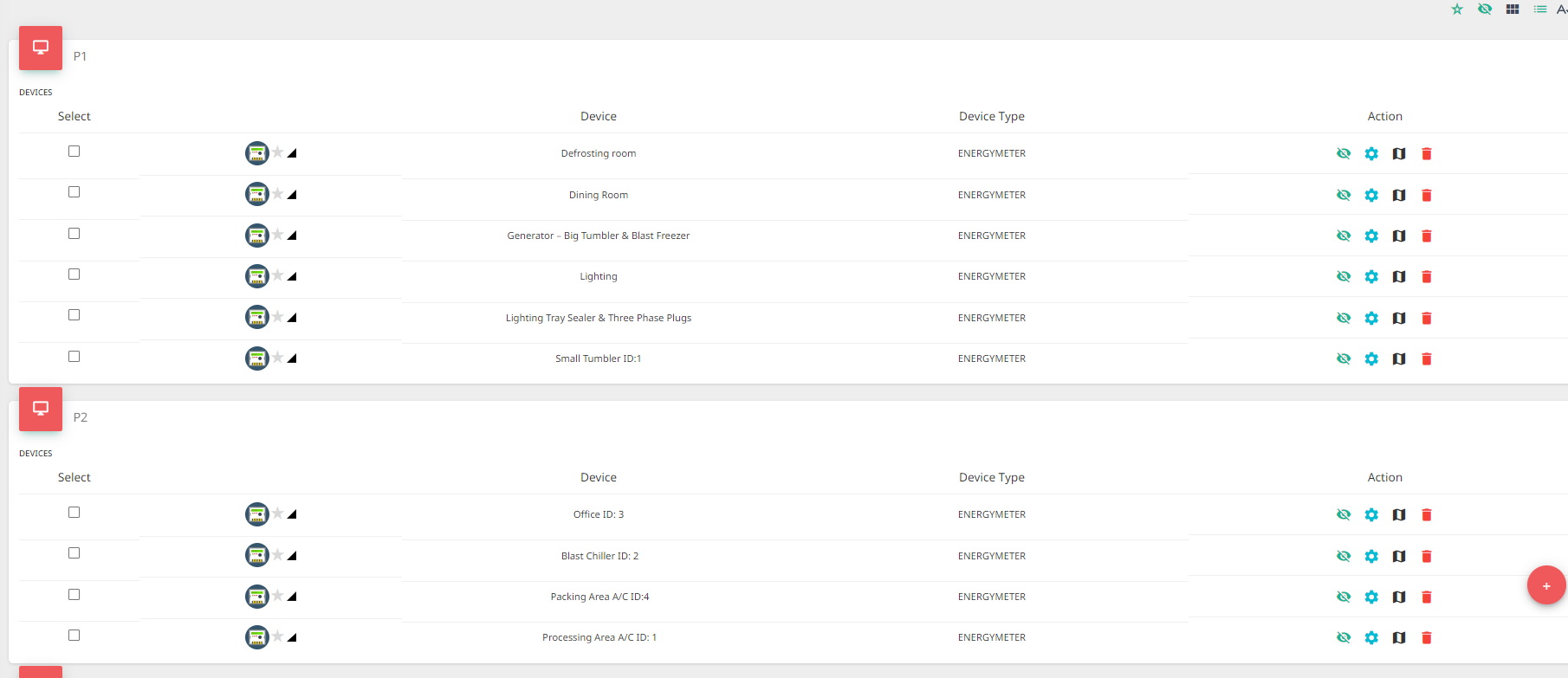

Triton Foods’ production line relies on a range of sophisticated machinery, including tumblers, defrosting rooms, tray sealers, blast chillers, and cold storage units. Additionally, the company utilizes regular consumption equipment such as lighting, air conditioning, and computers. To efficiently manage these power-hungry assets, Triton Foods sought a comprehensive energy monitoring solution.

Processing and Manufacturing Equipment Overview:

- Tumbler: The rotary tumbler is a crucial component in Triton’s food manufacturing process, ensuring even distribution of flavors and marinades.

- Defrosting Room with Thawing Machine: This room houses the thawing machine, a critical element for the defrosting process in the production of frozen foods.

- Tray Sealer: The tray sealer is responsible for securely sealing packaging, maintaining product freshness and integrity.

- Blast Chiller: Rapidly lowering the temperature of the food products, the blast chiller is essential for preserving quality and ensuring safety.

- Cold Storage Units (3): These units play a vital role in storing the frozen products before distribution, maintaining an optimal environment for long-term storage.

Regular Consumption Load:

Triton Foods faces consistent energy demands from lighting, air conditioning, and computers. To manage peak loads efficiently, a backup generator is employed, especially during high-demand processes like the operation of the rotary tumbler.

Shared Utility Bills

Sharing a tariff meter with an adjacent factory adds complexity to Triton’s utility billing. The challenge lies in accurately segregating the shared usage. To address this issue, Triton Foods sought a comprehensive energy monitoring solution.

The Solution: GoSwitchgear Advantage

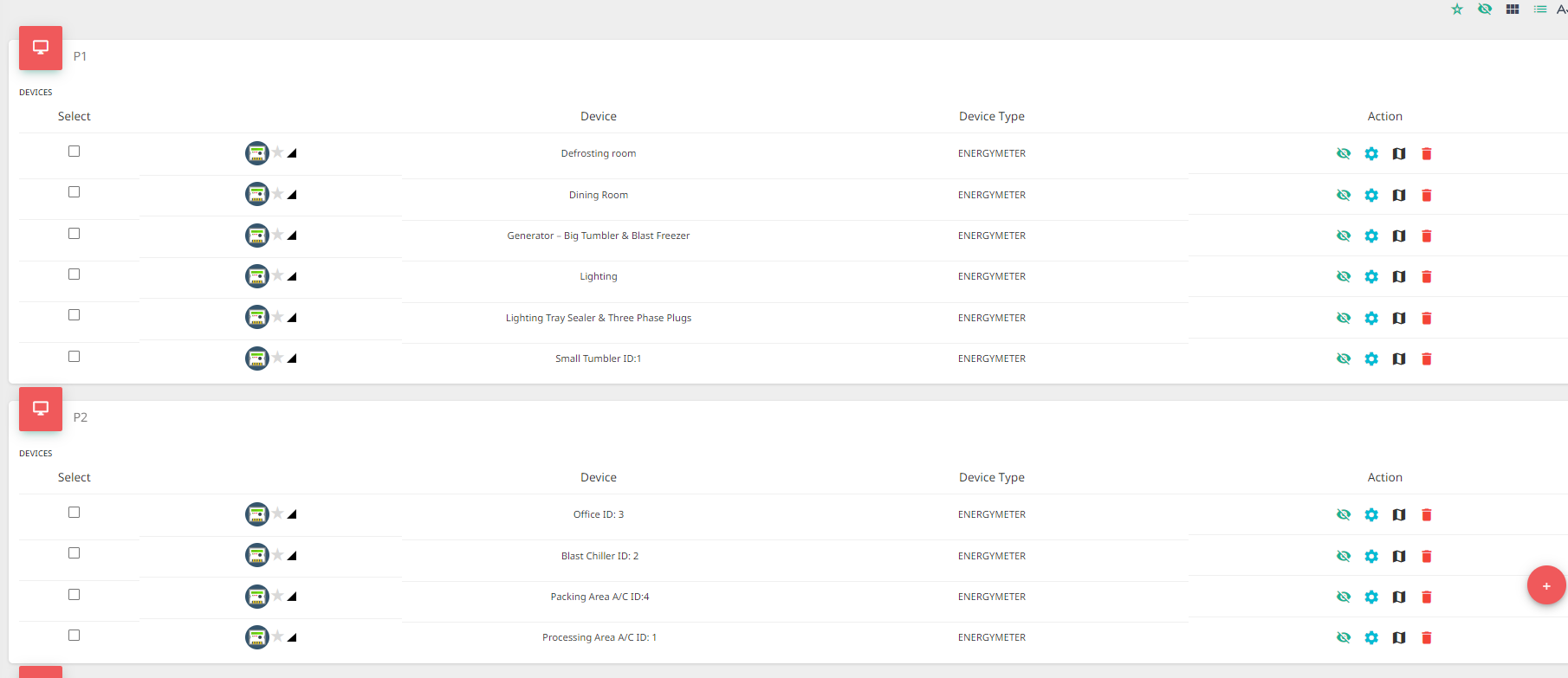

GoSwitchgear responded with a cutting-edge energy monitoring system, featuring an IoT 4G GSM gateway (MQTT gateway) at its core. This gateway seamlessly collects data from Multifunction Panel Meters installed on individual machines and equipment. The gathered information is then transmitted to a cloud server, forming the foundation for Triton Foods’ robust energy management infrastructure.

4G GSM MQTT Gateway

- IOT 4G GSM Gateway (MQTT Gateway): This gateway acts as the communication bridge, collecting real-time data from Triton’s Multifunction Panel Meters.

- Multifunction Panel Meters: Installed at individual machines and equipment, these meters measure energy consumption through the breakers in control panels.

- Cloud based monitoring Server and energy data logger: The collected data is seamlessly transmitted to a secure cloud server for storage and analysis. The benefits and features are explained in the next section.

Unveiling the Cloud Dashboard:

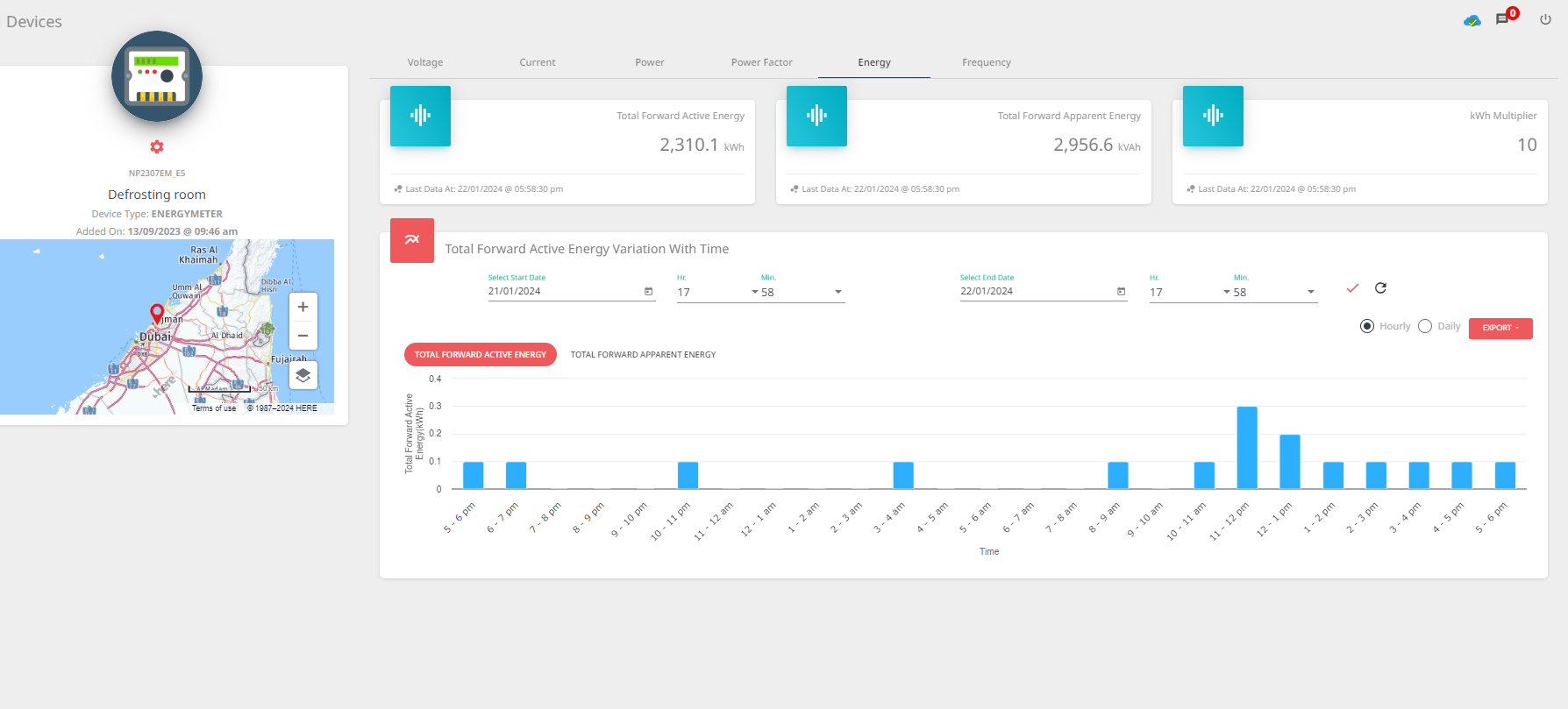

The heart of this energy monitoring system lies in its cloud dashboard. Designed with interactive features, this dashboard allows Triton Foods to access and monitor real-time energy consumption data. This user-friendly interface provides a comprehensive overview of both overall energy consumption and individual machine performance

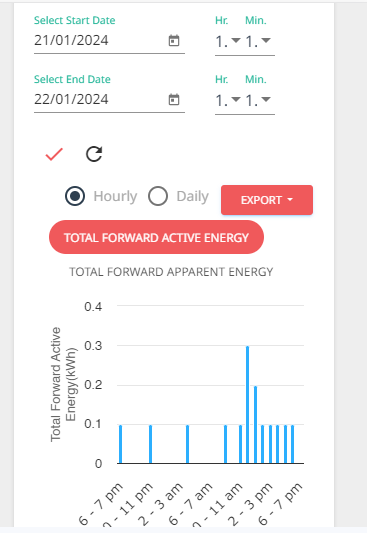

- Real-time Consumption Monitoring:

- Track energy consumption in real-time, enabling proactive decision-making.

- Individual Machine Analytics:

- Gain insights into the energy usage patterns of each machine, aiding in preventive maintenance and optimization.

- Peak Demand Analysis:

- Identify peak demand periods to strategize load management effectively.

- Runtime Monitoring:

- Monitor the operational hours of each machine to streamline production schedules.

- Overload Alerts:

- Receive instant alerts for potential overloads, preventing equipment damage and reducing downtime.

- Power Quality Metrics:

- Assess the power quality to ensure efficient and stable operations.

Benefits for Triton’s use-case

Individual Machine Insights:

- Gain a deep understanding of each machine’s energy consumption patterns.

- Identify peak demand periods, allowing for strategic scheduling to minimize costs.

- Track runtime, ensuring optimal performance and maintenance planning.

Load Optimization:

- Analyze overload instances to prevent equipment stress and potential breakdowns.

- Efficiently manage power quality to ensure a stable and reliable production environment.

Cost Reduction Strategies:

- Identify areas of improvement for energy efficiency across the production line.

- Implement data-driven decisions to reduce energy bills.

Achieving Sustainability Goals

With this state-of-the-art energy management system, Triton Foods is not only reducing its carbon footprint but also setting an industry benchmark for sustainable practices. The company’s commitment to optimizing energy usage aligns seamlessly with the United Arab Emirates’ vision for a greener and more efficient future.

Conclusion: A Brighter, Greener Future

Triton Foods’ partnership with GoSwitchgear exemplifies the transformative impact of smart energy metering and efficient energy management systems. By closely monitoring and optimizing energy consumption, Triton Foods is not only reducing operational costs but also contributing to a sustainable and environmentally conscious future. As the frozen food industry continues to evolve, Triton Foods stands at the forefront, showcasing the tangible benefits of embracing advanced energy solutions. The success of this project serves as a beacon for other industries in the United Arab Emirates looking to enhance their energy efficiency and environmental sustainability

Leave a Reply