Posted by:

Category:

Comments:

Post Date:

Top 5 Causes of Switchgear Failures & How to Prevent Them

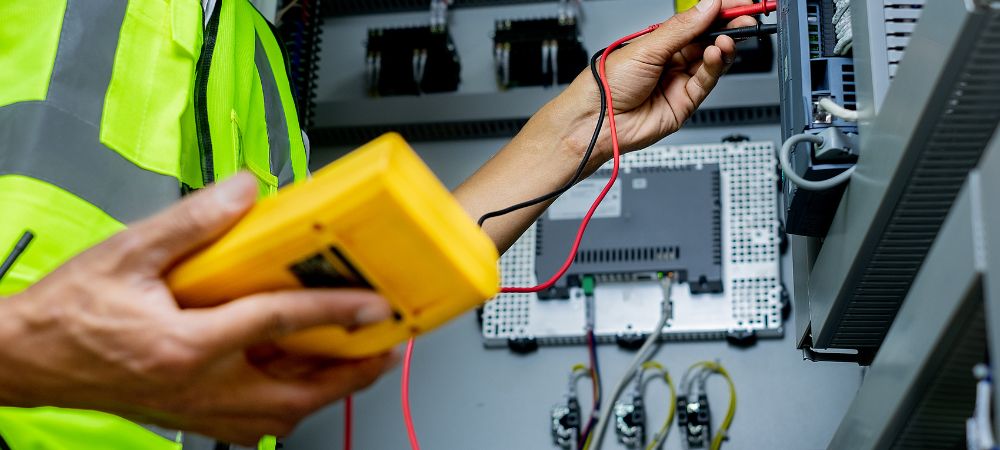

Switchgear is like the heart of an electrical system that manages an efficient and safe flow of power. However, sometimes, switchgear can run into failures. Any failure in its components can be the cause behind disruption, leading to downtimes or power outages. This is why maintaining the reliability of electrical switchgear is necessary, as it is crucial for both the continuity of the operation and safety.

Understanding the causes of switchgear failures can help identify risks early, while proactive switchgear maintenance strategies can prevent breakdowns. In this article, we are going to look into the most common reasons for switchgear failures and discuss practical ways to keep your systems running smoothly.

Quick Summary:

- A switchgear is a collection of devices that are used to keep an electrical system safe and under control. These devices are usually present inside a metal enclosure, and the switchgear helps manage, protect, and isolate the flow of power.

- Some of the common causes of switchgear failure include overheating, insulation degradation, mechanical failures, environmental factors, and improper maintenance.

- Preventing switchgear failure is simple; you need to schedule regular maintenance, ensure that it is installed properly, make sure that the enclosure is proper so that environmental factors won’t damage your system, and lastly, train and educate your staff regarding basic switchgear issues so they can be detected earlier before they become big problems.

What is a Switch Gear, and What Function Does it Perform?

What exactly is a switchgear? You can think of switchgear as a collection of devices that are used to keep an electrical system safe and under control. These devices are usually present inside a metal enclosure, and the switchgear helps manage, protect, and isolate the flow of power.

So, what does it include? Switchgear is a collection of important components, such as circuit breakers, fuses, switches, disconnectors, lightning arrestors, and other power conductors. All of these components play a significant role in the system.

But what does it actually do? Simply put, the switchgear is like a protective layer in an electrical system. These protect the system from electrical overload and power surges by automatically interrupting the flow of electricity. Not only that, switchgear makes maintenance easier as it lets you disconnect the circuit safely.

Top 5 Causes of Switchgear Failures

Now that you know what a switchgear is and the functions it performs in an electrical system, let’s have a look at some of the most common switchgear problems that it might run into, affecting the continuity of operation.

Overheating

Overheating is one of the most common switchgear failure modes that can occur due to several reasons, including:

- Overloaded circuits

- Loose connections within the switchgear

- Insufficient cooling systems

Overheating can be a huge risk factor, as it may lead to an increased risk of fire, damage to the internal components, and even lower switchgear reliability.

In order to address this issue, you need to monitor the temperature constantly and consider upgrading any outdated cooling mechanism.

With regular checks, you can rest assured that your equipment will not get damaged because of any unnecessary breakdowns caused by overheating.

To learn more about keeping your electrical system operating within safe temperature ranges, you can refer to our guide on low-voltage switchgear.

Insulation Degradation

Insulation degradation basically refers to the gradual deterioration or breakdown of insulation material in electrical systems. In switchgear and other electrical systems, insulation plays an important role, as it won’t let any current leak between conducting parts, leading to short circuits, equipment damage, or even fires.

Insulation degradation is one of the common switchgear fault causes, which can occur for a number of reasons, including:

- Excessive heat or moisture

- Physical stress or mechanical wear

- Environmental contaminants such as dust

Once the insulation starts degrading, it will weaken the dielectric properties and lead to short circuits and faults. That is the reason why it is important to constantly test the insulation and, if required, upgrade to a high-quality insulation material. Doing this would mitigate any risk associated with switchgear failures. Switchgear maintenance routines should always include insulation checks; this would make sure that your switchgear stays reliable for a long.

Mechanical Failures

Mechanical failure is inevitable, especially in switchgear components that are used frequently, such as contractors and circuit breakers. Mechanical failures occur because of:

- Wear and tear

- Corrosion from environmental exposure

- Damage due to lack of lubrication

How can you reduce the risk associated with mechanical failure? Switchgear troubleshooting and replacement of parts when they are worn out are techniques that might help. You should continuously upgrade your system so as to avoid any sudden failures that might disrupt the performance of your critical systems.

If you are looking to replace your electrical contractors and circuit breakers, head over to Go Switchgear. Get your hands on reliable and high-quality components that will keep your system running smoothly as well as safely.

Environmental Factors

Various environmental factors can also lead to switchgear failure:

- Humidity and moisture can cause corrosion and rust.

- Over time, dust and debris might accumulate on your system, which, if not cleaned, may lead to short circuits.

- Components or materials might become weak due to extreme temperatures. Extremely hot and cold temperatures may cause the materials to expand and contract.

In order to deal with issues caused by environmental factors, using control measures like humidity regulators, air filters, and sealing mechanisms becomes essential. Moreover, if your switchgear is properly designed, it will protect its components from dust, moisture, and temperature changes.

Improper Maintenance

One of the switchgear failures causes that is rather preventable is improper maintenance. Without proper maintenance, inspection, and servicing, components of the switch are likely to deteriorate faster. Improper maintenance can lead to:

- Unnoticed faults

- Delayed detection of potential failures

- Safety risks for personnel

Establishing a switchgear maintenance schedule will help you prevent switchgear failure and will also extend the lifespan of your equipment. Your switchgear maintenance schedule should include regular inspection, testing, and servicing.

Preventing Switchgear Failure: Strategies for Avoiding Failures

Now that we have covered the top 5 reasons behind the failure of switchgear let’s discuss some of the preventive measures and steps that you can take to keep your electrical system functioning well.

Routine Maintenance

Remember to schedule inspections and servicing regularly. Simple actions like checking for loose connections and checking for wear and tear can go a long way, helping you prevent unexpected breakdowns so everything keeps running smoothly.

Environmental Control

It is also necessary to protect your switchgear from environmental threats, as environmental factors such as humidity, dust, debris, and extreme temperatures can also cause switchgear failures. Choosing a proper enclosure for your system will keep it protected and safe.

Proper Installation

Sometimes, improper installation of components can also lead to failures. Hence, it is important to have the components installed by trained personnel.

Training and Awareness

Remember to also train and educate your staff on switchgear safety protocols and troubleshooting basics. A well-trained team would be able to identify small issues before they would become big problems.

Contingency Planning

It is always a good idea to be prepared for unforeseen circumstances. Having a backup system and response plans can save you a lot of trouble.

For more detailed insights on choosing protective systems, have a look at our guide on selecting the right electrical protection relays.

Over to You:

Switchgear failures are avoidable once you understand the causes and how to prevent them. Moreover, proactive strategies and regular maintenance can prevent switchgear failure as well.

Upgrade your electrical systems today. Visit GoSwitchgear or get in touch with our experts to find options that meet your needs and budget.

How often should you perform switchgear maintenance?

What are the signs of switchgear insulation degradation?

How does humidity affect switchgear?

What are some basic steps for switchgear troubleshooting?

- Start by inspecting visible components.

- Test insulation and check connections.

- Consult technical resources for complex troubleshooting cases.

Share this post

Related

Posts

Weatherproof & Waterproof Junction Boxes in the UAE: The Complete Guide (PVC & ABS)

In the UAE’s harsh outdoor conditions—intense heat, dust, humidity, and occasional storms—protecting electrical connections isn’t optional. It’s survival. Weatherproof and...

Digital Time Switch – Smart Timing Control for Industrial and Energy Efficiency in UAE & KSA

In today’s fast-paced industrial and commercial environments, precision control of time-based operations is no longer optional—it’s essential. Digital Time Switches,...

RISH Clamp vs RISH Clamp Power: Which Clamp Meter Should You Choose?

Selecting the right clamp meter is critical when working in industrial or energy monitoring environments. Rishabh Instruments, known for its...

Understanding Solar Panel Connectors: EMPV4N and EMPV10N Series

Quick Summary: This blog post provides a comprehensive guide on solar panel connectors, specifically the Elmex EMPV4N and EMPV10N series. It...