What is EMI Shielding? How it Protects Critical Power Systems

In today’s rapidly advancing world of electronics, electromagnetic interference (EMI) poses a significant threat to the reliability and functionality of electronic systems. From small consumer gadgets to massive power grids, EMI can disrupt sensitive equipment, causing malfunction, degradation in performance, and even complete failure of electronic components. This is where EMI shielding comes into play. But what is EMI shielding, why is it crucial, and how does it ensure the smooth operation of modern electronics? Let’s dive into the world of EMI shielding and understand its importance in modern power systems and other electronic devices.

What is EMI Shielding?

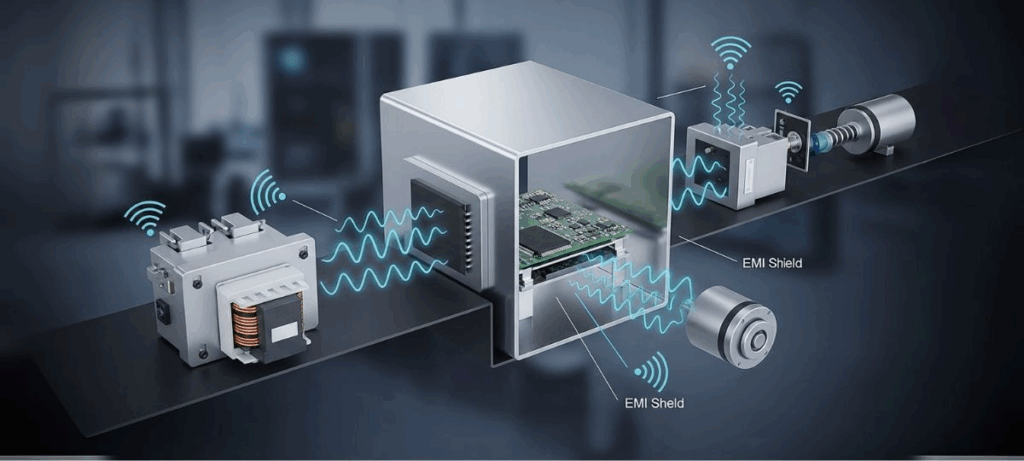

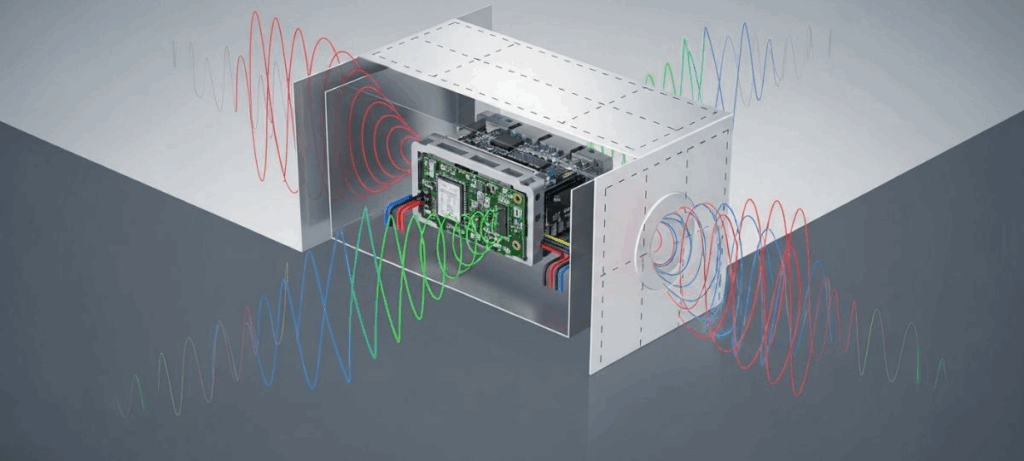

EMI shielding refers to the use of materials and techniques that protect electronic devices and systems from unwanted electromagnetic fields. It prevents the disruption of the performance of sensitive electronic components by blocking or reducing electromagnetic radiation that may interfere with them. This is accomplished by encasing electronic devices or systems with conductive or magnetic materials that either absorb or reflect the EMI waves.

Understanding Electromagnetic Interference (EMI)

Before going deeper into EMI shielding, it is essential to understand the source of the problem, electromagnetic interference (EMI). EMI is the disturbance caused by electromagnetic waves emitted by electrical devices. These waves can interfere with the operation of nearby electronic devices, leading to reduced performance, malfunction, or even failure of critical systems. EMI can be caused by various sources, such as:

- Powerful electrical equipment like transformers, motors, and generators.

- High-speed data transmission systems, such as wireless communication systems, satellites, and mobile phones.

- Switchgear equipment, which, in its operation, can create electrical noise that interferes with the proper functioning of nearby electronic systems.

Why is EMI Shielding Important in Modern Electronics?

As technology evolves, the need for EMI protection has grown exponentially. Devices today are more interconnected than ever, and the power and speed of electronic systems have increased. However, these advancements also come with the challenge of electrical noise and EMI that can compromise the reliability of these systems. EMI shielding plays a critical role in ensuring that modern electronic devices function efficiently and without disruption. Here are the key reasons why EMI shielding is essential:

1. Preventing Malfunctions and Failures

Without proper shielding, electromagnetic radiation can interfere with the signals and operations of various components. For example, in power distribution systems, EMI can affect the operation of protection relays, causing them to trip unnecessarily or fail to react when required. Devices such as surge protection devices also rely on clean, uninterrupted electrical signals to protect against voltage spikes. EMI can cause malfunction, rendering these protection devices ineffective.

Proper EMI shielding ensures that critical components, such as lightning protection systems, remain undisturbed by unwanted interference, which is vital for their correct functioning and longevity. It also helps to maintain the quality and efficiency of power systems, reducing downtime and improving the overall reliability of modern electronics. GoSwitchgear ensures that LV/MV switchgear, control panels, and power distribution units are designed with integrated EMI shielding to prevent interference and malfunctions in high-stakes environments.

2. Ensuring Compliance with Standards

Most modern electronic systems are required to meet specific electromagnetic compatibility (EMC) standards to minimize the risk of EMI affecting nearby devices. These standards are crucial in industries such as telecommunications, automotive, medical, and industrial control systems. Without effective EMI shielding, devices may fail to meet these regulatory requirements, risking fines, recalls, or even market ban.

For companies like GoSwitchgear, ensuring that products meet EMI and EMC standards is crucial. GoSwitchgear’s electrical shielding solutions are specifically designed to help customers comply with international standards, ensuring that systems operate efficiently without violating EMC regulations. This makes GoSwitchgear’s LV/MV switchgear and other power systems highly reliable for commercial and industrial use.

3. Protecting Sensitive Equipment

Sensitive equipment, especially in critical infrastructure, is highly vulnerable to the effects of EMI. In high-stakes environments like hospitals, power stations, and control rooms, even the smallest disruption in the operation of equipment can have serious consequences. EMI shielding materials help safeguard these critical systems from the harmful effects of EMI. By preventing interference, EMI shielding ensures that equipment like protection relays, surge protection devices, and power distribution units continue to function correctly, minimizing the risk of downtime.

In sectors that depend on sensitive data, such as telecommunications and healthcare, EMI shielding is vital to maintain data integrity and secure communication. Devices like smartphones, computers, and medical equipment must operate without interruption from nearby electronic devices. Effective EMI protection ensures smooth and reliable operation in these environments, and GoSwitchgear’s solutions are specifically tailored to these needs, especially for critical power systems.

4. Reducing Signal Degradation

In modern electronic systems, signal integrity is crucial. Whether it’s in communication systems, power grids, or computing devices, the quality of the signal is paramount. Electromagnetic shielding helps prevent external noise from degrading the signal, ensuring that the transmission is clean and stable.

EMI shielding materials are specially designed to absorb or reflect electromagnetic waves, preventing these waves from disrupting signals. In systems such as lightning protection systems, where high-voltage spikes can cause interference, effective shielding is essential for maintaining the integrity of signals.

5. Protecting Power Systems from Electromagnetic Disturbances

Power systems, such as switchgear units and transformers, are particularly vulnerable to EMI due to the high voltages they deal with. High-frequency noise generated by nearby equipment can cause electrical shielding issues, leading to equipment malfunction or failure.

To mitigate the effects of EMI on critical power systems, advanced EMI control shielding solutions are used. These solutions include the integration of specialized materials into switchgear and electrical panels. At GoSwitchgear, EMI shielding is a key component in ensuring the proper operation of MV and LV switchgear designs, which are critical to maintaining power quality and system reliability. GoSwitchgear utilizes high-performance materials to minimize electrical noise, ensuring its products comply with industry standards.

Types of EMI Shielding Materials

There are various EMI shielding materials available, each with its unique properties suited to specific applications. Common types of EMI shielding materials include:

- Conductive metals: These are the most common materials used for EMI shielding. They include metals such as copper, aluminum, and steel, which are excellent at conducting and reflecting electromagnetic waves.

- Magnetic materials: These materials, such as mu-metal, are used to shield against low-frequency electromagnetic fields. They absorb magnetic energy, preventing it from affecting nearby systems.

- Electromagnetic absorbers: These materials are used to absorb EMI energy. They can be applied in applications where the reflection of electromagnetic waves is not ideal.

- Composite materials: These combine the benefits of multiple materials, such as metals and polymers, to offer a balance between flexibility and shielding effectiveness.

At GoSwitchgear, we carefully select these materials based on the needs of each application. For example, copper and aluminum are used for their conductivity in LV/MV switchgear, while mu-metal is employed for low-frequency shielding in high-power environments.

How Does EMI Shielding Work?

EMI shielding works by either reflecting or absorbing electromagnetic waves. Materials used in EMI shielding are designed to create a barrier around electronic systems that either deflects or absorbs unwanted electromagnetic radiation. This prevents the EMI from entering the system and causing interference with its normal operation.

In modern power systems, such as those utilized by GoSwitchgear, electromagnetic shielding helps reduce interference from external sources, ensuring that the system continues to function without disruption. For example, GoSwitchgear’s advanced EMI shielding solutions are specifically designed to block high-voltage spikes and electrical noise, ensuring the protection and longevity of critical systems.

Conclusion

EMI shielding is a vital component in the design and operation of modern electronics, particularly in critical power systems. Whether it’s for surge protection devices, lightning protection systems, or protection relays, effective EMI shielding ensures that devices operate efficiently and without disruption. By preventing the harmful effects of electromagnetic interference, EMI shielding helps protect sensitive equipment, maintain signal integrity, and comply with EMC regulations.

At GoSwitchgear, EMI shielding is an integral part of their LV and MV switchgear designs, ensuring that critical power systems operate reliably and efficiently. Through the use of advanced EMI shielding materials and electromagnetic shielding techniques, GoSwitchgear provides solutions that safeguard against electrical noise, reduce downtime, and enhance the performance of power systems.

FAQ’s

What is EMI Shielding?

EMI shielding is a methodology that involves blocking or reducing electromagnetic interference that might interfere with an electronic device’s function, especially in critical power systems.

How does EMI Shielding protect power systems?

EMI ensures that electromagnetic waves do not interrupt sensitive equipment in a protection scheme, including circuit breakers and surge protection devices. Such protections reliably work and create safety in operation.

What are common EMI shielding materials?

The general usage ranges from metals such as copper and aluminum to conductive polymer shielding; all these have various advantages based on application.

What is Shielding Effectiveness (SE)?

Shielding Effectiveness is the extent or quality of a material to stop electromagnetic waves from getting through. The value of SE is directly related to the effectiveness of the material in providing protection against EMI.

What standards do GoSwitchgear’s EMI shielding solutions comply with?

GoSwitchgear’s EMI shielding solutions comply with international standards, including IEEE, IEC, and MIL-STD, for electromagnetic compatibility.

Can GoSwitchgear customize EMI shielding solutions for specific applications?

Yes, GoSwitchgear offers customized EMI shielding designs tailored to client requirements and specific application environments.

What is the lifespan of GoSwitchgear’s EMI shielded switchgear?

The EMI shielded switchgear is built for durability, with a typical lifespan of 20–30 years under standard operating conditions.

Leave a Reply