Relays and Contactors: Differences and Key Functions

Relays and contactors are commonly used to control electrical circuits for different applications such as low voltage switchgear panels, industrial motor control circuits and electrical power distribution.

What are relays and contactors, and what are the key differences between these electric instruments?

Relays

Institute of Electrical and Electronics Engineers, IEE defines relays as “a device by means of which contacts in one circuit are operated by a change in conditions in the same circuit or in one or more associated circuits”. Though the above definition is quite precise, it lacks some clarity on an application and operational level. Hence, we can define it once again as a switch that controls the opening and closing of the circuit using electromagnetic or electromechanical properties. Based on the type and configuration of the relay, different conditions (such as overload) will trigger the electromagnetic armature of the relay which will open on close the electronic circuit. The relay can have Normally Open (NO) or Normally Closed (NC) contacts, which means unless triggered the contacts will stay in NO or NC states.

The conditions which can trigger the switch can be overload, overcurrent, reverse-current, over and under-voltage.

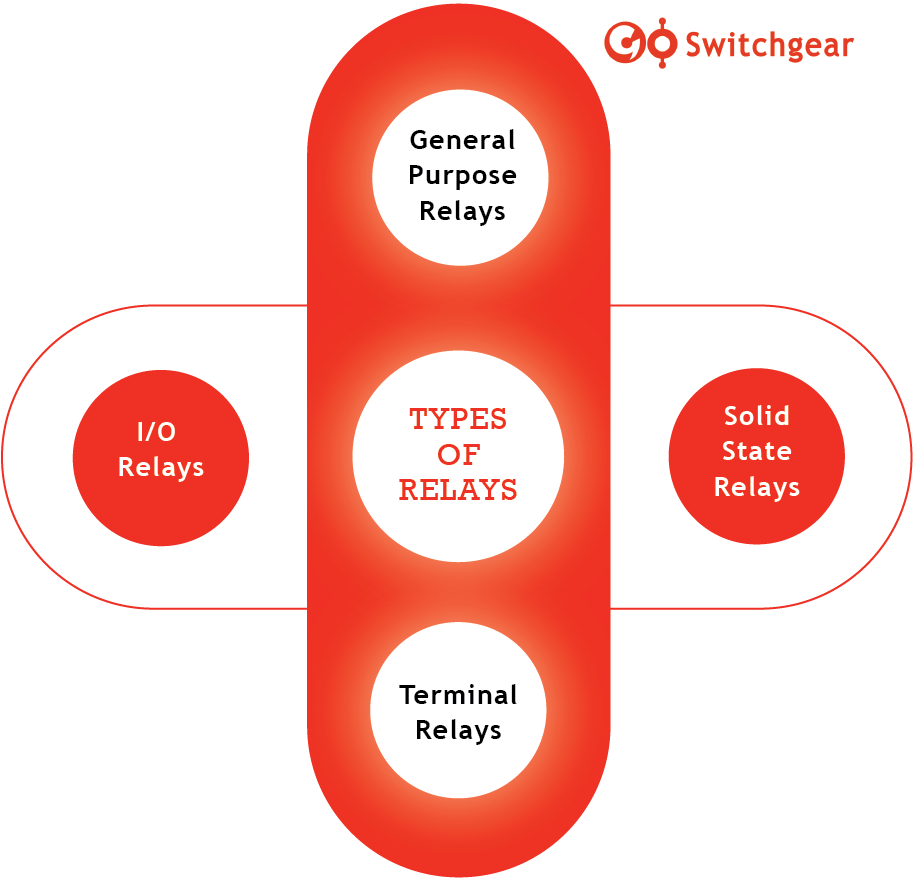

Apart from electromagnetic operations, relays also have induction type, solid-state, and magnetic latching relays, which have a different mode of operation.

Once energy is supplied (charge or electricity) to the switch (can also call it a signal) the NO or NC states are prone to change, thus enabling the relay to control the circuit.

Solid-state relays operate without the movement of any components in the relay.

Relay types also exist based on polarity, i.e. polarized relays and non-polarized relays.

GoSwitchgear provides a few types of relays, such as under-voltage relays (UVR) and earth leakage relays (ELR) by Veritek Instruments.

Contactor

The general working principle of Contactors and relays is very similar. The IEE definition for contactor is “a device for repeatedly establishing and interrupting an electric circuit under normal conditions”.

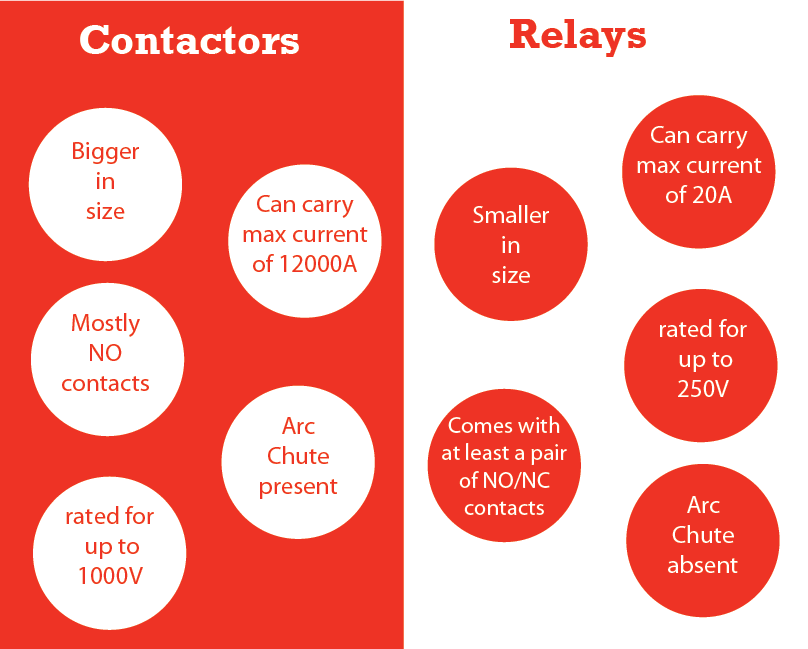

It can be described as a special type of relay used in higher current applications. They are also compact and easily field mounted. Contactors can have multiple contacts, with commonly Normally Open (NO contacts) which provide power to the load when the coil is energized which causes the switch to trigger.

Contactors are most commonly used for motor control applications along with a PLC which provides the control signal (charge or electricity). They are even used for thermal overload applications when paired with a thermal overload relay.

Mainly three types of contactors exist,

- Magnetic Contactors,

- Knife blade switch contactor

- Manual Controller contactor

You can find two types of contactors, capacitor duty contactors (capacitor switching contactors) and power contactors at the Go Switchgear online store.

The key differences between Contactor and Relay

Comment (1)

[…] Learn more about relays, and the key points that differentiate them from contactors in this article- (Medium blog/ GoSwitchgear Blog). […]