Choosing the Right PVC Electrical Conduit for Projects in the UAE & GCC

For any electrical installation in the UAE's demanding climate, the choice of conduit is critical. It's the backbone of your project's longevity and compliance. That's why PVC electrical conduit, an advanced energy management solution, has become the go-to for engineers and electricians across Dubai and the wider GCC. It offers robust protection against the extreme heat, humidity, and corrosive elements that define the region.

Why PVC Conduit Is a Must-Have for Modern UAE Projects

As a professional managing electrical systems in the UAE or KSA, you know that protecting your wiring is the first critical step. The region's unique environment—intense sun, high humidity, and pervasive dust—can destroy subpar materials, leading to system failures, safety risks, and costly rework. While traditional metal conduits offer strength, they often succumb to corrosion, especially in coastal cities like Dubai or Abu Dhabi.

This is where Polyvinyl Chloride (PVC) electrical conduit excels. It’s not a simple plastic tube; it's an engineered system designed for durable, reliable, and compliant protection of electrical wiring. Unlike metal, PVC is inherently immune to rust and chemical corrosion, making it the ideal material for the salty, humid air prevalent throughout the Gulf. This is a key feature for any energy management solution in Dubai.

The Strategic Edge in a Demanding Environment

Choosing PVC conduit is more than a material swap; it's a strategic decision impacting your project's timeline, budget, and long-term reliability. Its lightweight nature is a game-changer, significantly reducing labor costs and installation time—a major advantage for large-scale commercial and industrial projects in the GCC where efficiency is paramount.

Furthermore, its non-conductive properties provide an automatic layer of safety, lowering the risk of electrical faults. When specifying materials for your next project, these benefits are crucial:

- Superior Corrosion Resistance: PVC does not rust or degrade when exposed to moisture, salt, or common chemicals, ensuring your wiring system remains intact for decades.

- Cost-Effectiveness: With lower material and installation costs, PVC is a smart economic choice that avoids compromising on quality or safety.

- Enhanced Safety: As a non-conductive material, it helps prevent dangerous phase-to-ground faults, a critical safety feature for any electrical installation.

- Ease of Installation: Its light weight and flexibility make on-site handling, cutting, and assembly straightforward, accelerating project timelines from start to finish.

For engineers and procurement managers, the key is sourcing high-quality, certified materials. A trusted supplier like GoSwitchgear provides access to PVC electrical conduit that meets stringent local and international standards (like IEC and GCC). This ensures your project is built to last and achieves regulatory approval without delays.

Decoding the Different Types of PVC Conduit

Navigating the world of PVC electrical conduit boils down to selecting the right tool for the job. For procurement teams, engineers, and electricians working on projects across the UAE and GCC, understanding the different types is non-negotiable. This decision directly impacts project success, safety compliance, and the bottom line.

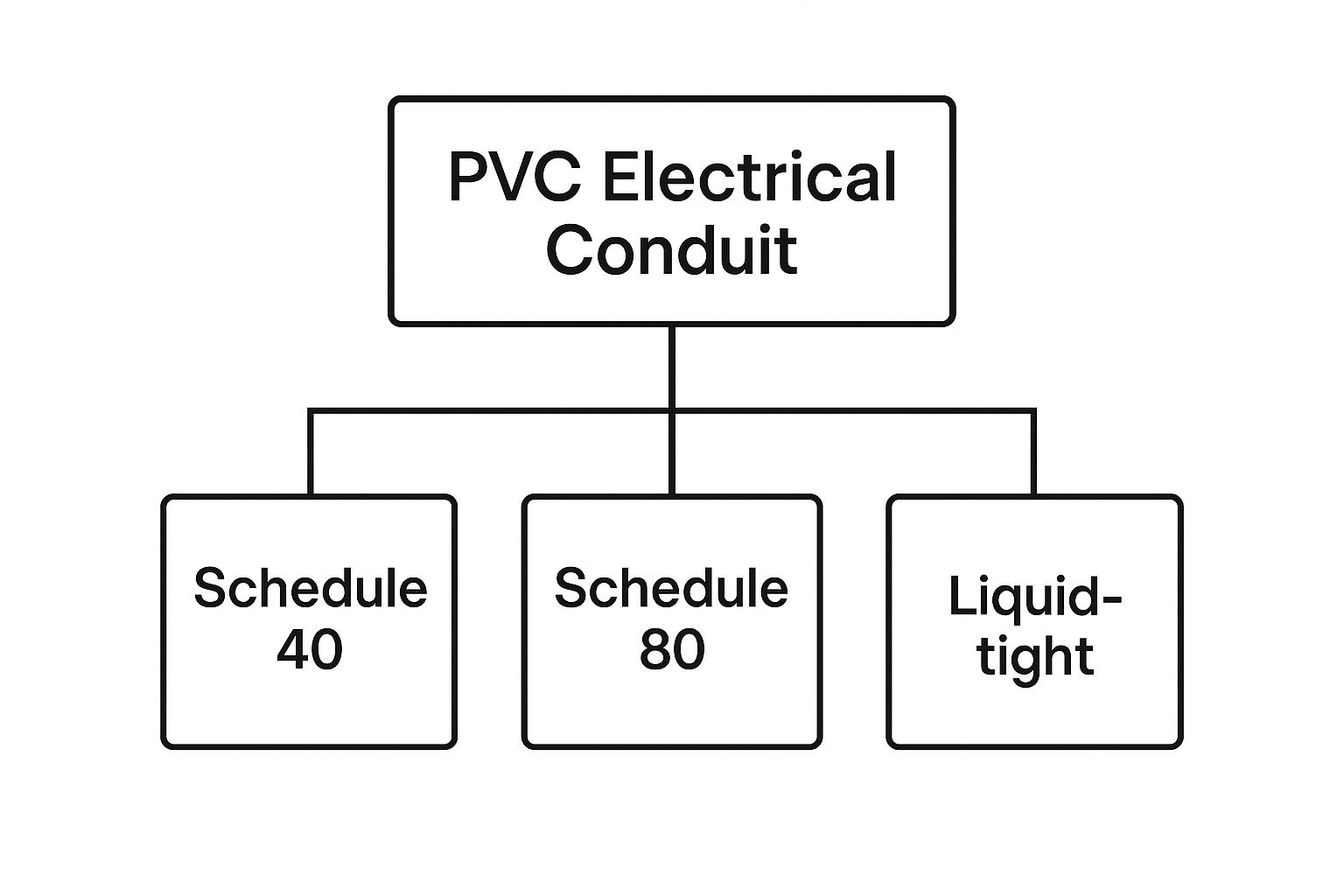

PVC conduit is primarily classified by its "Schedule" rating, which denotes the wall thickness. The most common are Schedule 40 and Schedule 80, alongside flexible options for complex installations.

This diagram illustrates the relationship between these categories.

As shown, the primary distinction is between rigid and flexible conduit. Rigid types are further categorized by wall thickness, which determines their resistance to physical impact.

Schedule 40 PVC Conduit

Consider Schedule 40 PVC conduit the reliable workhorse for most commercial and residential electrical projects. Its thinner wall makes it lighter, easier to handle, and more budget-friendly for standard applications.

Its main function is to protect wiring concealed within walls, ceilings, and other locations shielded from significant physical impact. For many high-rise towers in Dubai or commercial hubs in Abu Dhabi, Schedule 40 provides the perfect balance of protection, affordability, and rapid installation.

Schedule 80 PVC Conduit

When your project demands maximum durability, Schedule 80 PVC conduit is the answer. Its significantly thicker wall offers far greater resistance to impacts and crushing forces, making it the go-to choice for challenging environments.

Specify Schedule 80 for applications such as:

- Industrial facilities where it may be exposed to machinery or vehicle traffic.

- Underground installations directly buried without concrete encasement.

- Exposed outdoor runs in high-traffic areas where contact is likely.

It is the armoured guard for your electrical system's most vulnerable pathways. While it carries a higher cost and is more rigid to work with, this investment is crucial for the long-term integrity of systems in harsh GCC conditions.

Flexible PVC Conduit

For complex installations where rigid conduit is impractical, Flexible PVC Conduit offers exceptional adaptability. It can be bent by hand, making it ideal for connecting to vibrating machinery, navigating tight corners, or routing wires around obstacles.

This versatility is driving its popularity. The prewired flexible conduit market in the Middle East and Africa is a fast-growing segment, projected to reach USD 142.50 million in 2024. Experts forecast a CAGR of about 7.7% through 2031, driven by industrial and commercial projects requiring both mechanical protection and routing flexibility. You can explore the full market analysis on Cognitive Market Research for deeper insights.

A key product in this category is Liquid-Tight Flexible Non-Metallic Conduit (LFNC). This specialized version features a smooth interior for easy wire pulling and a tough, sealed outer jacket. It provides superior protection against moisture, oils, and dust—an absolute necessity for many industrial settings in the GCC.

Quick Comparison of PVC Conduit for GCC Projects

To simplify your decision, this table compares the features, applications, and climate suitability of different PVC conduit types for projects in the UAE and GCC.

| Conduit Type | Key Feature | Primary Application | Best for GCC Climate (Heat, Humidity, Dust) |

|---|---|---|---|

| Schedule 40 | Lightweight, cost-effective | General purpose, concealed in walls/ceilings | Excellent for indoor/protected areas; requires UV protection for direct sun exposure. Good IP rating when sealed. |

| Schedule 80 | Thick-walled, high impact resistance | Industrial, underground, and exposed high-traffic areas | Ideal for harsh outdoor and industrial settings with high heat, potential impact, and dust. |

| Flexible (LFNC) | Bendable, liquid-tight seal | Connecting equipment, navigating tight spaces | Perfect for industrial areas with high exposure to moisture, oil, and dust (high IP rating). |

Ultimately, selecting the right conduit requires anticipating the real-world stresses—environmental and physical—your electrical system will face. Matching the conduit to the application ensures a safe, compliant, and durable installation every time.

The Unbeatable Advantages of PVC in the GCC Climate

When specifying electrical components in the UAE, performance is non-negotiable. The region's unique combination of intense heat, relentless humidity, and corrosive coastal air is a brutal proving ground. This is where PVC electrical conduit demonstrates its superiority, offering powerful advantages that traditional materials like metal cannot match.

For professionals in Dubai, Abu Dhabi, or KSA, the choice of conduit directly impacts the safety and reliability of the entire electrical system. PVC’s inherent characteristics make it the clear winner for this tough environment, delivering a dependable and budget-friendly solution built to last.

Innate Corrosion Resistance for Coastal Longevity

Atmospheric corrosion is a major challenge in the GCC. The salty, humid air common in coastal cities is notoriously hostile to metal. Even galvanized steel conduits will eventually rust, compromising the raceway and exposing the wires within.

PVC, however, is completely unaffected by salt and moisture due to its chemical inertness. It will not corrode, rust, or degrade, ensuring the electrical system remains sealed and protected for its entire service life. This makes PVC electrical conduit the optimal choice for any project near water or in high-humidity industrial areas.

This built-in corrosion immunity translates directly to lower maintenance costs and fewer replacements over the project's lifespan—an "install and forget" solution that offers both long-term peace of mind and significant financial savings.

Enhanced Safety Through Non-Conductivity

Safety is paramount in any electrical installation. Metallic conduits are conductive and require flawless grounding. A single faulty connection can energize the entire conduit system, creating a massive shock hazard.

PVC eliminates this risk entirely.

As a non-conductive material, it cannot carry an electrical current. This natural insulating property adds a vital, built-in layer of safety, simplifying installation and drastically reducing the risk of phase-to-ground faults. This is a significant advantage in complex projects where ensuring a perfect ground across a large metal system is challenging.

Practical Benefits On-Site: Lightweight and Easy to Handle

Beyond its technical strengths, PVC offers significant practical advantages during construction. It is substantially lighter than steel, a difference felt immediately on-site.

- Easier Transport: Moving bundles of PVC conduit around a large project site, like a high-rise or industrial plant, requires less effort and machinery.

- Faster Installation: Electricians can handle, cut, and join PVC electrical conduit more quickly and with less fatigue, directly speeding up project timelines.

- Reduced Labor Costs: Easier transport and faster installation lead to a direct reduction in labor hours, making a noticeable impact on the bottom line.

Smooth Interior for Flawless Wire Pulling

Pulling cables through the conduit is a critical final step. The interior surface of the raceway is crucial. Metal conduits can have rough patches or sharp edges, especially at cuts, which can snag or damage expensive cable insulation.

PVC conduit, by contrast, has an exceptionally smooth interior. This low-friction surface allows wires to glide through long runs and around bends with minimal resistance and a lower risk of damage. This protects the cables and simplifies final termination, ensuring clean and secure connections. For a complete understanding of this final step, see our guide on electrical cable lugs types.

How to Select the Right PVC Electrical Conduit

Choosing the right PVC electrical conduit is a critical decision that impacts the safety, budget, and compliance of your project. For engineers and project managers in the UAE and GCC, it's a careful balance between specific project demands and the harsh environmental realities of our region.

This is about more than just diameter; it's about considering the entire installation lifecycle. What voltage will the wires carry? What punishing conditions will the conduit face for decades? This practical guide will help you navigate these factors to make a technically sound and commercially smart choice.

Start with Project-Specific Electrical Needs

Your first step is to analyze the electrical system itself. The type and size of the conductors will dictate the minimum internal diameter of the conduit. Overfilling a conduit is a serious code violation that can lead to dangerous overheating and damaged cables.

Ask these key questions:

- What are the voltage levels? High-voltage applications often have specific rules for insulation and spacing that influence your conduit choice.

- What type of wiring are you using? The flexibility and insulation rating of your cables affect how easily they can be pulled.

- What is the required conduit fill ratio? You must consult local regulations (e.g., DEWA, ADDC) and IEC standards, which specify the maximum permitted fill percentage to prevent heat buildup.

Assess the Installation Environment

Next, analyze the physical environment. The GCC climate—with its extreme heat, high humidity, and fine dust—strains all building materials. A high IP (Ingress Protection) rating is essential for any electrical components in the UAE to guard against dust and moisture.

A common mistake is underestimating direct sunlight. Standard PVC can become brittle under relentless UV radiation. For outdoor runs on rooftops or exposed walls, specifying UV-resistant PVC electrical conduit is not optional; it's essential for preventing long-term system failure.

For installations near industrial zones or coastal areas, also consider exposure to chemicals and salty air. While PVC is naturally corrosion-resistant, confirm that your chosen grade is rated for any specific chemicals it may encounter.

Match the Conduit to Physical Stresses

A conduit run encased in a concrete wall has different protection needs than one on a busy factory floor. This is where understanding the difference between Schedule 40 and Schedule 80 is crucial.

- How to Choose Schedule 40: This is your go-to for most commercial and residential jobs where the conduit is protected from physical harm.

- When to Use Schedule 80: With its thicker wall, Schedule 80 is the only choice for areas with high physical stress, such as industrial environments, direct underground burial, or any exposed location where it could be hit.

Choosing a lighter-duty conduit to save on initial cost in a high-impact area is a false economy that almost always leads to expensive repairs and downtime.

Prioritise Compliance and Certification

In the UAE and KSA, regulatory compliance is mandatory. The PVC electrical conduit you select must comply with international standards like IEC 61386 and specific local utility requirements. Insisting on certified products is the only way to ensure materials will pass inspection and perform as expected. Pairing certified conduit with other approved components, like those in our guide to cable tray accessories, creates a fully compliant system.

The scale of this market is massive. The Middle East and Africa polyvinyl chloride (PVC) market was valued at about USD 3.41 billion in 2024. Experts project it will swell to around USD 4.67 billion by 2032, fueled by the enormous infrastructure and urbanization projects sweeping the region. As you can learn more about the PVC market growth on Verified Market Research, it becomes clear why specifying certified, top-quality materials is so critical.

Mastering PVC Electrical Conduit Installation

Even the highest-quality PVC electrical conduit is only as good as its installation. For any electrician in the UAE, proper installation is about long-term safety, reliability, and compliance. This is where real-world skill turns pipes and fittings into a durable raceway that can withstand the punishing GCC climate.

Mastering installation means focusing on the details at every step. The following best practices ensure the system can handle the heat, seal out moisture, and protect wiring for years to come.

Best Practices: Cutting, Deburring, and Joining

The integrity of any conduit run begins with a clean cut. A rough, angled cut will not bond properly and can leave sharp burrs that damage wire insulation during pulling.

Follow this installation procedure for a solid connection every time:

- Measure and Cut: Use a fine-toothed saw or a dedicated PVC cutter for a perfectly square cut. This ensures the pipe sits flush inside the fitting.

- Deburr Every Edge: Use a deburring tool or utility knife to clean the inside and outside edges of the pipe. This is key to preventing wire damage.

- Apply Solvent Cement: First, apply a purpose-made PVC primer, followed by solvent cement. Apply a thin, even layer to the outside of the conduit and a slightly heavier coat to the inside of the fitting.

- Join, Twist, and Hold: Immediately push the conduit into the fitting with a slight twisting motion until it bottoms out. Hold it firmly for at least 30 seconds to allow the chemical weld to set, creating a permanent, watertight seal.

Proper Support Spacing for the GCC Climate

A common installation failure in the UAE and GCC is conduit sag. In high heat, improperly supported PVC electrical conduit will soften and droop. This strains the joints and can create low spots where moisture collects.

Maintenance Best Practice: Adhering to manufacturer and local code requirements for support spacing is non-negotiable. For a typical 3/4-inch (20mm) conduit, supports are often required every 3 feet (approximately 1 metre). This prevents sagging and maintains structural integrity under high ambient temperatures.

For vertical runs, place supports within 3 feet of every termination point (e.g., junction boxes, panels) to prevent the weight of the conduit and cables from pulling connections apart over time.

Common Installation Mistakes to Avoid

Knowing these common pitfalls is the best way to avoid rework and ensure your job passes inspection.

- Over-tightening Fittings: When working with threaded adapters, over-tightening can crack the PVC fitting, creating a weak point. Hand-tighten, then add a final quarter-turn with a wrench.

- Ignoring Thermal Expansion: PVC expands and contracts with temperature changes. For long, straight runs exposed to the sun, you must install expansion joints. Forgetting this can cause the conduit to buckle or pull apart.

- Improper Bending Techniques: Bending conduit in the field requires proper technique. Using excessive heat from a blowtorch can weaken the PVC. Always use a proper heating tool, like a hotbox bender, and follow manufacturer instructions.

By focusing on these techniques and avoiding common mistakes, your PVC electrical conduit installation will be up to code and built for decades of reliable service.

Staying Compliant: How to Navigate UAE Electrical Standards

In the UAE and GCC, compliance is paramount. Ensuring every component, especially something as fundamental as PVC electrical conduit, meets stringent local and international standards is the bedrock of a successful project. It's about safety, longevity, and the integrity of your entire electrical installation.

For engineers and procurement managers, navigating these regulations is non-negotiable. Partnering with a trusted supplier like GoSwitchgear, who provides materials with the necessary certificates of conformity, is a strategic move that mitigates risk and prevents costly project delays.

The Standards That Truly Matter

The key international standard is IEC 61386, which governs conduit systems. It outlines critical performance requirements, testing everything from mechanical strength and impact resistance to heat and moisture protection. A PVC electrical conduit with IEC 61386 certification is a product proven to perform.

Beyond international standards, you must follow the specific rules of local utility authorities like the Dubai Electricity and Water Authority (DEWA) and the Abu Dhabi Distribution Company (ADDC). Their guidelines often dictate installation techniques, material grades, and support spacing tailored to the region's tough conditions.

A common project derailer is the use of non-certified materials. These products lack traceability, and when local authorities request documentation, there is none to provide. The result is immediate rejection, forcing a complete material replacement and consuming a significant portion of the budget.

Keeping Up with Market Growth and Quality Sourcing

The demand for high-quality electrical components is booming. The electrical conduits market across the Middle East and Africa was valued at around USD 450.72 million in 2023 and is projected to hit USD 635.98 million by 2032, driven by massive infrastructure projects. As the market expands, identifying certified materials is essential. You can get a better sense of these trends by exploring a deeper analysis of these market dynamics.

To ensure your project gets approved without issues, always demand the following from your supplier:

- Certificate of Conformity (CoC): Official proof that the product meets required safety and quality benchmarks.

- Manufacturer Test Reports: Hard data showing how the product performed in tests against standards like IEC 61386.

- Traceability: The conduit must be clearly marked with the manufacturer's name and the standards it meets.

By prioritizing certified materials from trusted partners, you are investing in compliance, safety, and the long-term success of your project in the demanding UAE market.

Got Questions About PVC Conduit? We've Got Answers.

When it comes to projects in the UAE and across the GCC, our engineering and installation partners often have some great questions about PVC electrical conduit. Let's dive into the most common ones to clear up any confusion and make sure your next installation is safe, compliant, and built to last.

Can I Use Standard PVC Conduit in Direct Sunlight Here in the UAE?

It's a common question, and the short answer is no. Standard PVC conduit is not designed for the intense, prolonged sun exposure of the GCC. Over time, UV radiation will degrade the material, making it brittle and creating a serious failure point.

For any outdoor application, you must use UV-resistant PVC conduit. This type contains special additives that protect it from sun damage, ensuring long-term durability.

How Do I Handle Thermal Expansion on Long Conduit Runs?

With the temperature swings in this region, thermal expansion is a critical factor. For long, straight sections of conduit, you must install expansion joints at the intervals recommended by the manufacturer.

These fittings allow the PVC electrical conduit to expand and contract with the heat. Without them, the run will either buckle under pressure or pull itself apart at the joints.

The difference between a system that lasts five years and one that lasts thirty often comes down to accounting for environmental factors like thermal expansion. A small expansion joint can prevent catastrophic failure on a sun-beaten rooftop run.

Is PVC Conduit Okay for All Types of Electrical Installations?

While PVC is incredibly versatile, it has its limits. It cannot be used in hazardous locations with flammable gases or dust. In those environments, metallic conduit is required for proper grounding and containment.

Always check local electrical codes and specific requirements from authorities like DEWA or ADDC to confirm PVC is suitable for the application. In some cases, you might need to use armoured cables. We dive deeper into that topic in our guide to armoured cable sizes.

What's the Real Difference Between Schedule 40 and Schedule 80?

It all comes down to wall thickness and impact resistance.

- Schedule 40 is the standard choice for most commercial and residential applications where the conduit is protected within walls or ceilings.

- Schedule 80 has a much thicker wall, providing superior physical protection. It is specified for tough industrial environments, underground runs not encased in concrete, and any exposed area where it might be struck.

For expert guidance in selecting the right PVC electrical conduit and ensuring your project meets all regional standards, the GoSwitchgear team is ready to assist. Our team in Dubai can provide project support and help you source the right electrical components in the UAE.

Leave a Reply