Selecting the Right Flexible Electrical Conduit for UAE & GCC Projects

Staring at a complex wiring route in a modern Dubai high-rise or a sprawling industrial plant in Saudi Arabia? The blueprints show a path that's anything but straight, and rigid conduits won't cut it. This is where flexible electrical conduit becomes a critical solution, providing the adaptive backbone for tight, winding, and unpredictable spaces where rigid systems simply fail.

Why Flexible Conduit is a Game-Changer for UAE & GCC Projects

The construction and industrial sectors across the UAE and the wider GCC demand speed, efficiency, and resilience. While traditional rigid electrical conduits have their place, they create significant challenges in complex layouts, building retrofits, or connecting machinery prone to vibration. This is where the practical advantages of a superior energy management solution like flexible electrical conduit shine.

The core benefit is adaptability. For engineers and electricians on the ground in Dubai or Abu Dhabi, this means fewer complex bends and offsets to measure and create. This translates directly into faster installation and lower labour costs—a crucial advantage against tight project deadlines.

Performance in Demanding GCC Environments

The operational environment in the Gulf region—with its extreme heat, humidity, dust, and vibration—tests the limits of all electrical components UAE. Flexible electrical conduit is engineered to thrive in these specific conditions.

- Vibration and Movement: In an industrial plant or commercial building, HVAC units, pumps, and generators are constantly vibrating. A rigid conduit transfers these mechanical stresses directly to wires and connections, risking fatigue and failure. Flexible conduit absorbs these vibrations, safeguarding circuit integrity.

- Complex Routing: Modern buildings and infrastructure retrofits rarely offer a straight shot for wiring. Navigating around obstacles and through cramped spaces is standard. Flexible conduit handles this with ease, eliminating the on-site cutting, threading, and bending that rigid pipes demand.

Meeting Regional Growth Head-On

As the region's infrastructure expands, so does the demand for reliable wiring solutions. The Middle East and Africa (MEA) flexible electrical conduit market was valued at USD 33.05 million in 2024, highlighting its indispensability for critical projects across the UAE and KSA. You can review more data on this market trend and its drivers to understand the full scope.

Key Takeaway: For any project in the GCC, choosing flexible electrical conduit is a strategic decision. It ensures system longevity, boosts safety in dynamic environments, and offers a practical solution to installation challenges common in the region's advanced infrastructure.

Matching Conduit Types to Your Application

Choosing the right flexible electrical conduit isn't a one-size-fits-all decision, especially in the demanding environments across the UAE and GCC. For procurement teams and panel builders, focusing on real-world performance is critical. The right choice ensures the safety, longevity, and compliance of your electrical installation, preventing costly rework and premature failures.

The material, construction, and protective features of the conduit must perfectly match the operational and environmental challenges it will face—from a dry indoor data centre to a humid, coastal application in Dubai.

The Core Types of Flexible Electrical Conduit

Understanding the main categories is the first step. Each type offers distinct advantages for different applications.

- Flexible Metallic Conduit (FMC): Often called "Greenfield," this is made from a helically wound, interlocking strip of aluminium or steel. FMC is an excellent choice for dry, indoor locations where flexibility is needed but moisture is not a concern.

- Liquid-Tight Flexible Metal Conduit (LFMC): This is FMC's tougher sibling. It features the same metallic core but adds a seamless, waterproof plastic outer jacket. This jacket provides robust protection against moisture, oils, and certain chemicals, making it essential for outdoor use, industrial wash-down areas, and HVAC installations.

- Non-Metallic Liquid-Tight Flexible Conduit (FNMC): Built from flame-retardant PVC, this conduit is a lightweight, corrosion-proof alternative to its metal counterparts. FNMC is the go-to choice for environments with high humidity, saltwater exposure (common in coastal cities like Dubai and Jeddah), and where corrosive chemicals are a concern.

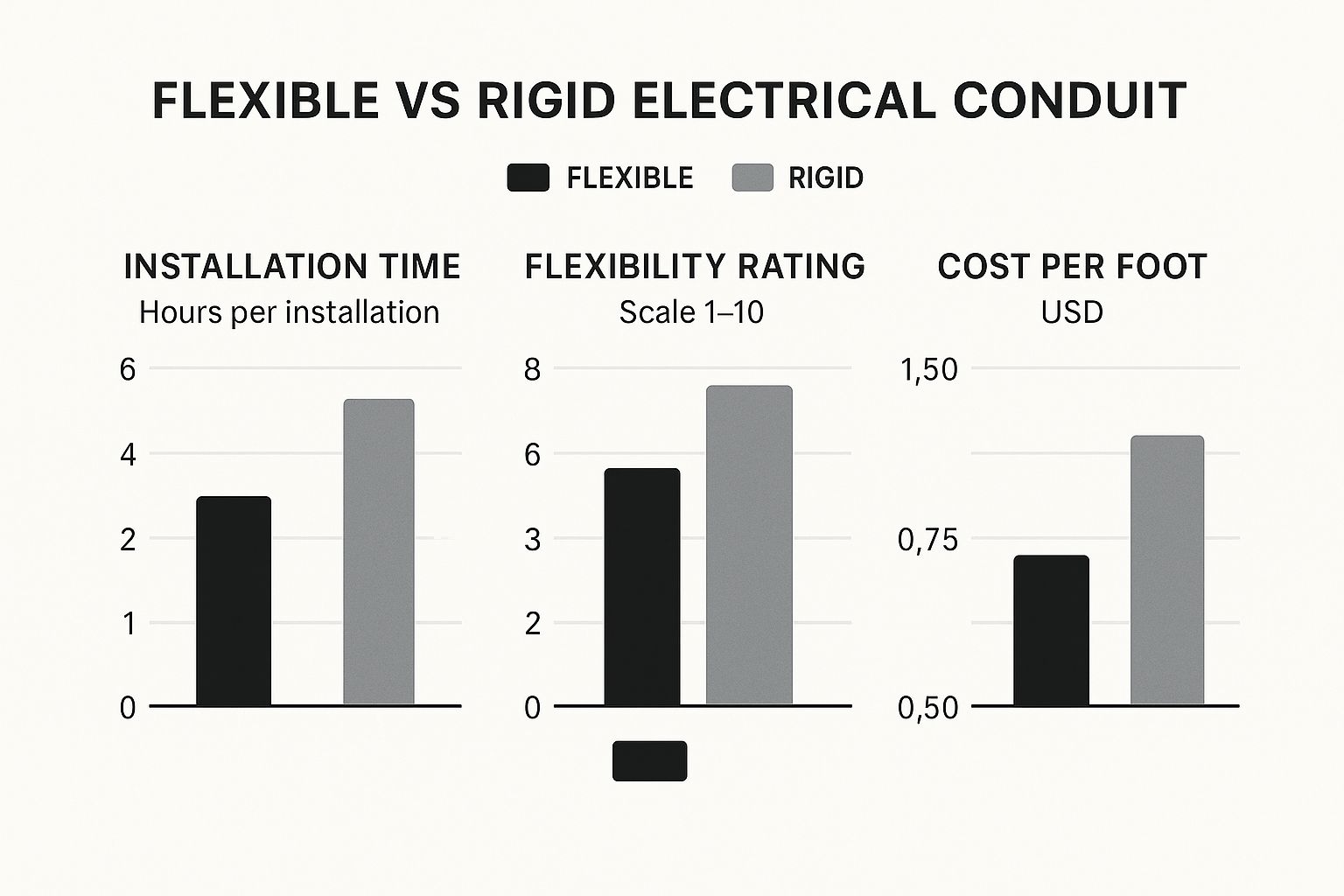

The primary benefits of flexible conduit are significantly faster installation and superior adaptability, making it a cost-effective solution for projects with complex wiring routes.

Quick Comparison of Flexible Conduit Types

This table helps you quickly match the right conduit to your project's environmental and performance needs, with specific considerations for the GCC region.

| Conduit Type | Core Material | Key Benefit | Ideal UAE Application | IP Rating Range |

|---|---|---|---|---|

| FMC | Steel/Aluminum | High flexibility, crush resistance | Dry indoor data centers, office fit-outs | IP40 |

| LFMC | Steel/Aluminum | Watertight, oil-resistant | Outdoor HVAC units, factory machinery | IP66, IP67 |

| FNMC | PVC | Corrosion-proof, lightweight | Coastal projects, chemical plants, marinas | IP66, IP67 |

This at-a-glance view simplifies the decision, ensuring you select a conduit that will perform and last.

Matching Materials to UAE and GCC Conditions

The choice between metallic and non-metallic conduit often depends on the specific environmental pressures of the installation site.

A common mistake is specifying a conduit based on flexibility alone, without considering its material resilience. In the GCC's climate, a conduit's ability to resist heat, UV radiation, and humidity is just as important as its ability to bend.

Keep these material-based factors in mind:

- Crush Resistance: For high-traffic industrial settings, a galvanized steel core (in FMC and LFMC) offers superior protection against crushing.

- Temperature Tolerance: All electrical components in the UAE must handle high ambient temperatures. Always check the manufacturer's datasheet for the conduit's operating temperature range to ensure it won’t degrade in the summer heat.

- Corrosion Resistance: For projects near the coast or in chemical plants, Non-Metallic Liquid-Tight Flexible Conduit (FNMC) is ideal. Its PVC construction is immune to rust and corrosion, guaranteeing a longer service life. For a deeper look, see our guide on choosing the right PVC electrical conduit for projects in the UAE and GCC.

By carefully analyzing the application, you can confidently specify the flexible electrical conduit that delivers the best performance and value.

Decoding IP Ratings and GCC-Specific Requirements

Choosing the right flexible electrical conduit in the GCC is a high-stakes decision driven by a harsh climate and strict regulations. An outdoor installation in Dubai is constantly exposed to fine desert dust, extreme heat, and high humidity. These are relentless forces that can destroy substandard electrical protection.

Selecting the wrong conduit leads to system failure, operational downtime, and safety hazards. Engineers and procurement specialists must be fluent in Ingress Protection (IP) ratings. These codes are a certified promise of a product's environmental resilience—a critical factor for any electrical gear in the UAE.

Demystifying IP Ratings for Conduit Selection

An IP rating, defined by IEC 60529, indicates how well a conduit protects its internal components.

- First Digit (Solids): Ranging from 0 to 6, this shows protection against solid objects. For the GCC, IP6X is the gold standard, signifying the conduit is completely dust-tight—non-negotiable for outdoor or industrial applications where sand is a daily reality.

- Second Digit (Liquids): Ranging from 0 to 9, this indicates moisture protection, from dripping water (IPX1) to high-pressure jets (IPX9).

A conduit rated IP67 is fully sealed against dust and can be temporarily submerged in up to one meter of water, making it a reliable choice for many outdoor and industrial sites across the region.

GCC Compliance and Local Authority Standards

Beyond IP ratings, compliance with local standards is mandatory. Authorities like the Dubai Electricity and Water Authority (DEWA) and their counterparts in Abu Dhabi and Saudi Arabia have strict regulations. Specifying a flexible electrical conduit that meets their requirements is crucial for project approval.

When sourcing from a supplier like GoSwitchgear, you must confirm compliance with relevant International Electrotechnical Commission (IEC) standards, which often form the basis of local regulations. This verification is a key part of any thorough electrical risk assessment.

Expert Insight: In the salty air of coastal cities like Jeddah or Sharjah, a conduit's material is as crucial as its IP rating. Standard galvanized steel will corrode. For these areas, specifying a Non-Metallic Liquid-Tight Flexible Conduit (FNMC) or a stainless steel version is the smarter choice for long-term rust protection.

How to Read a Datasheet for Compliance

The manufacturer's datasheet is your most critical tool.

Checklist for Datasheet Review:

- IP Rating: Ensure it’s clearly stated (e.g., IP67) and valid when used with proper connectors.

- Material Specification: Identify the core and outer jacket materials. For outdoor use, look for UV-resistant PVC jackets.

- Operating Temperature Range: The conduit must perform reliably in ambient temperatures that can exceed 50°C.

- Certifications: Look for markings showing compliance with IEC, UL, or other international standards recognized by local authorities.

By carefully decoding IP ratings and verifying compliance, you can confidently choose a flexible electrical conduit that delivers safety and long-term reliability.

Flexible Conduit in Action Across UAE Industries

While technical specifications are important, the real value of flexible electrical conduit is seen in its application across the UAE's most demanding sectors. Its adaptability is a core solution to daily engineering challenges.

From industrial plant floors to the hidden backbones of commercial towers, its applications are diverse and critical. In a busy Jebel Ali manufacturing plant, heavy machinery vibrates 24/7. Rigid conduit would fatigue and fail. Flexible conduit absorbs these vibrations, safeguarding wiring and ensuring operational safety.

Industrial and Commercial Applications

In high-stakes industrial and commercial projects, flexible conduit addresses unique structural and environmental hurdles.

- Data Centers and Commercial Towers: The maze of HVAC ducts, plumbing, and structural beams in a Dubai Marina high-rise makes wiring a nightmare. Flexible conduit is the only practical way to navigate these tight spaces, dramatically speeding up installation for critical systems.

- Outdoor Security and Lighting: Security cameras, perimeter lights, and access control systems installed outdoors in the UAE must withstand intense sun and humidity. Liquid-tight flexible conduit creates a sealed pathway that locks out moisture and dust, ensuring these vital systems remain operational. Should issues arise, a specialist in industrial electrical repair can efficiently troubleshoot these setups.

Renewable Energy and Specialized Use Cases

As the UAE expands its clean energy portfolio, flexible conduit has found a new role. In large-scale solar farms, it connects panels and inverters, accommodating thermal expansion and ground settlement. This resilience is key to the long-term performance of these green energy assets.

At its core, flexible conduit is a problem-solver. It is chosen not just for its flexibility, but because it protects electrical circuits where rigid systems would compromise safety and uptime.

The Rise of Prewired Flexible Conduit

A significant shift in the GCC is the adoption of prewired flexible conduit. This product arrives on-site with wires already installed, offering a major time-saving advantage for contractors on tight schedules.

It slashes on-site labour, reduces the risk of wire damage during pulling, and minimizes installation errors. The regional market for prewired flexible conduit was valued at USD 142.5 million in 2024 and continues to grow, signaling a clear demand for smarter, more efficient solutions.

Installation Best practices and Mistakes to Avoid

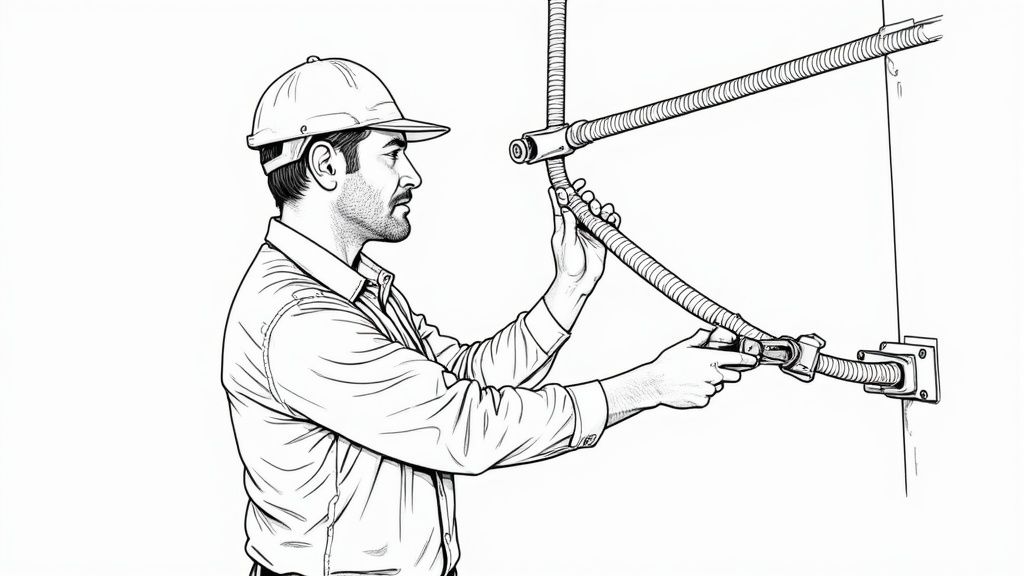

Even the best flexible electrical conduit is only as good as its installation. For electricians and technicians across the UAE, proper installation is non-negotiable. It is the final step that guarantees the safety, lifespan, and compliance of the entire electrical system.

A professional installation requires the right tools, correct fittings, and adherence to proven best practices to prevent costly rework and ensure durability in the harsh GCC environment.

Proper Cutting and Preparation Techniques

A clean cut is essential. A sloppy cut creates a weak point at the fitting, compromising the IP rating.

For Metallic Conduit (FMC & LFMC):

- Use a rotary cutter designed for flexible conduit to achieve a clean, square cut without crushing the core.

- Avoid using a hacksaw, as it leaves sharp burrs that can damage wire insulation, creating a safety hazard.

- Deburr any sharp edges after cutting.

For Non-Metallic Conduit (FNMC):

- A standard PVC cutter or a fine-toothed saw works well.

- Ensure the cut is perfectly straight and square to achieve a tight, reliable seal at the connection.

Securing and Supporting Your Conduit

Unsupported conduit will sag, putting stress on the conduit and its termination points, especially in the high temperatures of the UAE.

Secure flexible conduit at least every 1.4 meters (4.5 feet) and within 30 cm (12 inches) of every junction box or fitting. Use proper straps or clamps; never use zip ties or wires for permanent support, as they can damage the conduit's jacket.

A common mistake is assuming a short run can support itself. Gravity will eventually cause the conduit to sag and fail at the connector.

Common Installation Mistakes to Avoid

Being aware of common mistakes is the best way to prevent them on your projects in Dubai, Abu Dhabi, or elsewhere in the GCC.

- Over-Tightening Connectors: Applying excessive force can crack the fitting, strip threads, or crush the conduit's jacket, destroying its liquid-tight seal. Tighten firmly, but never force it.

- Exceeding Fill Capacity: Never fill a conduit more than 40% of its internal area with three or more wires. Overstuffing prevents proper heat dissipation, degrading insulation and creating a fire risk.

- Ignoring the Bend Radius: Always respect the manufacturer's minimum bend radius. Forcing a tighter bend will kink the conduit, damage its structure, and make it difficult to pull wires.

- Using Indoor-Rated Conduit Outdoors: Standard FMC offers no protection from humidity and rain. For any outdoor job in the GCC, you must use Liquid-Tight Flexible Metal Conduit (LFMC) or Non-Metallic Liquid-Tight Flexible Conduit (FNMC) for a safe, lasting installation.

The Future of Electrical Systems in the Middle East

The rapid development across the Middle East is creating a complex and power-hungry future.

National initiatives like Saudi Vision 2030 and ambitious UAE infrastructure projects demand an electrical backbone that is powerful, resilient, and adaptable. In this environment, flexible electrical conduit plays a surprisingly critical role.

The growing demand for all conduit types is a direct indicator of new construction, industrial expansion, and technological upgrades. This is about laying the essential groundwork for the smart cities and advanced manufacturing plants that will define the GCC's future.

A Market That Mirrors Ambition

The market data confirms this growth. In 2023, the Middle East and Africa's electrical conduit market generated revenues of USD 736.2 million.

With a projected compound annual growth rate (CAGR) of 6.4% through 2030, the market is set to exceed USD 1.1 billion. This surge is fueled by massive infrastructure investments. You can explore more insights on the MEA electrical conduit market.

This trend highlights a shift in thinking. As electrical systems become more complex, the need for wiring solutions that can navigate tight spaces and withstand harsh environments is non-negotiable.

Final Takeaway: Selecting the right conduit is a foundational decision that directly impacts project timelines, operational safety, and long-term reliability, safeguarding the multi-billion-dollar investments pouring into the region.

Your Partner in Building the Future

In this fast-changing landscape, your supplier choice is as crucial as your product choice. You need a knowledgeable partner who understands the unique challenges of projects in Dubai, Abu Dhabi, and the wider GCC.

Every detail matters, from ensuring compliance with local utility regulations to specifying materials that can handle extreme heat and humidity. The success of the region's most ambitious projects depends on getting these foundational elements right.

As a leading supplier of a wide range of electrical components UAE, GoSwitchgear is more than a distributor. We are an essential resource, ready to support the engineers and contractors building the resilient electrical systems of tomorrow.

Got questions about flexible conduit? Here are common queries from engineers and procurement specialists across the UAE.

Can I Use Flexible Metal Conduit Outdoors in the UAE?

Standard Flexible Metal Conduit (FMC), or 'Greenfield', is strictly for indoor use as it offers no moisture protection.

For any outdoor application in the UAE, you must use Liquid-Tight Flexible Metal Conduit (LFMC) or Non-Metallic Liquid-Tight Flexible Conduit (FNMC). Their sealed jackets are designed to keep out water, dust, and humidity.

What Is the Correct Fill Capacity for Flexible Conduit?

The international standard is to never fill more than 40% of a conduit's internal space when running three or more wires.

Overfilling is a major fire risk due to improper heat dissipation, which can melt insulation. Always check the latest DEWA or other local utility regulations for project-specific requirements.

How Do I Properly Ground a Flexible Metal Conduit Installation?

You cannot rely on standard FMC alone for grounding, especially for runs longer than 1.8 meters (6 feet), as its spiral construction is not a reliable ground path.

The safest and required method is to run a separate equipment grounding conductor (a green insulated or bare copper wire) inside the conduit. This ensures a dependable ground path, which is non-negotiable for safety in commercial and industrial settings.

This step ensures the system remains safely grounded, even if connections loosen over time.

For expert support on selecting the right flexible electrical conduit and compliant components for your projects in Dubai and Abu Dhabi, reach out to our team for project support.

Leave a Reply