Mastering Electrical Risk Assessment: A Guide for Safer UAE & GCC Projects

In the high-stakes industrial and commercial sectors of the UAE, a formal electrical risk assessment is a core business strategy, not just a compliance checkbox. For engineers and procurement teams, it's the foundation separating a profitable operation from catastrophic failure, ensuring the safety and resilience of every project in the GCC region.

Why an Electrical Risk Assessment is Non-Negotiable in the UAE

For professionals on the ground in Dubai and Abu Dhabi, an electrical risk assessment is an active tool to neutralize dangers unique to our local operating environment. The goal is to create a structured plan ensuring our electrical systems are not just operational but resilient and safe throughout their lifecycle. An energy management solution for a Dubai facility must begin with this fundamental step.

This systematic approach is critical for several reasons:

- Protecting Human Life: It systematically identifies potential arc flash, electric shock, and electrocution hazards, allowing for life-saving controls before an incident.

- Ensuring Operational Continuity: It pinpoints system weaknesses to prevent equipment failures that cause crippling downtime and lost production.

- Safeguarding Assets: It protects high-value assets—from switchgear to sensitive control panels—from being destroyed by electrical faults.

- Meeting Regulatory Compliance: It guarantees installations align with standards from local authorities like DEWA and ADDC, as well as international IEC standards.

The Amplifying Effect of the GCC Climate

The unique environment in the UAE and broader GCC introduces severe challenges that a standard assessment might miss. Failing to account for these factors significantly increases the risk of electrical failure.

These climate-related hazards are common culprits:

- Extreme Ambient Heat: Relentless heat puts constant thermal stress on components like circuit breakers and transformers. Incorrectly specified parts, like an SMPS power supply not rated for high temperatures, will age faster and fail prematurely.

- High Humidity and Salinity: In coastal cities like Dubai, humid, salt-laden air corrodes electrical connections, terminals, and enclosures, increasing the risk of short circuits.

- Dust and Sand Ingress: Fine desert dust can penetrate poorly sealed panels, impeding cooling, creating conductive paths, and damaging sensitive electronics.

An electrical risk assessment in the UAE must analyze these environmental impacts. This means selecting electrical components UAE suppliers like GoSwitchgear offer with high IP (Ingress Protection) ratings and applying correct temperature derating to ensure reliable performance.

The Regional Context of Industrial Growth and Risk

The explosive industrial growth across the UAE and the Middle East has led to complex electrical systems in manufacturing, oil and gas, and data centers. This boom brings hazards that demand meticulous safety management.

The challenge is often inconsistent safety programs, mixing international standards with a diverse workforce. This fragmentation creates a critical need for a unified electrical risk assessment framework. For deeper insights, dss+ offers some great insights on implementing robust electrical safety programs in the region.

Ultimately, this assessment is a non-negotiable part of project planning and asset management—the most reliable way to build a resilient electrical infrastructure that protects your people and your bottom line.

Setting the Stage for an Effective Assessment

An effective electrical risk assessment starts long before the on-site inspection. Careful preparation ensures the review is thorough and useful. When your team arrives, they must have everything needed to do the job right the first time.

First, clearly define the scope. Is it a single machine, a production line in an Al Quoz factory, or the entire electrical system for a new commercial tower in Abu Dhabi? A fuzzy scope wastes time and risks missing critical hazards. Be specific about the physical boundaries and equipment included.

Assembling the Right Team for the Job

Your assessment is only as good as the people performing it. The best teams blend different perspectives for a 360-degree view of the electrical system.

For any serious project in the UAE, your core team should include:

- A Certified Electrical Engineer: The technical authority who understands design principles, schematics, and load calculations.

- An Experienced Electrician or Technician: The hands-on expert who knows the practical side of installation and the tell-tale signs of wear.

- A Facility or Maintenance Manager: The holder of "tribal knowledge"—maintenance history, recurring issues, and how equipment is really used.

- A Safety Officer (NEBOSH/IOSH Certified): Ensures the assessment is conducted safely and aligns with the broader health and safety framework.

When these roles collaborate, they catch issues that would otherwise be missed. The engineer might spot a design flaw, while the electrician notices a dangerously modified panel that doesn't match the drawings.

Pro-Tip: For complex or high-risk facilities in the KSA or UAE, consider a third-party consultant. An outside expert offers an unbiased perspective, free from internal politics or "familiarity blindness," which can uncover hidden risks.

Gathering Your Essential Documentation

Starting an assessment without the right paperwork is like navigating Dubai without a map. Before any site visit, gather and review all key documents to understand how the system was designed versus how it exists today.

Your pre-assessment document checklist should include:

- Single-Line Diagrams (SLDs): The architectural blueprints of your electrical system.

- Equipment Manuals & Datasheets: Vital for understanding operational limits and maintenance needs, especially for critical gear from suppliers like GoSwitchgear.

- Maintenance and Testing Records: The system's biography, showing past failures, repairs, and recurring problems.

- Previous Risk Assessment Reports: Build on past findings to spot trends and check if previous fixes were implemented.

- Local Utility Regulations (e.g., DEWA/ADDC Guidelines): Ensure your assessment criteria align with mandatory local standards.

This strategic preparation allows your team to focus on identifying hazards, not chasing down basic information. For older systems with spotty documentation, this may require a deeper dive, potentially involving professional industrial electrical repair. Getting this groundwork done ensures your assessment is efficient and produces actionable insights for your UAE or GCC project.

Uncovering Hazards Before They Become Incidents

This is the detective work of an electrical risk assessment: moving past the obvious to find subtle risks unique to the fast-paced industrial environments across the GCC. The goal is a systematic walkthrough blending technical inspection with an understanding of human behavior.

A proper site inspection is a hands-on process, searching for signs that point to a brewing problem.

Imagine inspecting an electrical panel in a dusty Jebel Ali free zone facility. Here’s what experienced eyes look for:

- Signs of Overheating: Discolored wires, melted insulation, or a distinct burning smell near connections are major red flags indicating loose terminations or an overloaded circuit.

- Evidence of Corrosion: In humid coastal areas like Dubai, be vigilant for rust or greenish-white buildup on terminals, busbars, and enclosure hardware. Corrosion increases resistance, creating heat.

- Improper Modifications: Unofficial wiring changes, such as mismatched wire gauges or bypassed safety devices, are common and incredibly dangerous violations of local regulations.

- Dust and Debris Buildup: In industrial settings, dust traps heat and can create a conductive path. Check that ventilation fans are spinning and filters aren't clogged.

Beyond the Panel: A Broader Site Perspective

The hazard hunt extends beyond the main distribution board. A comprehensive assessment must evaluate the entire electrical ecosystem, from the power source to the end-user equipment.

Consider assessing temporary power on a sprawling Abu Dhabi construction site. The focus shifts to the entire setup. Are cables protected from vehicle traffic? Are connections insulated against moisture? Are generators correctly earthed? These are the questions that matter.

A critical part of any electrical risk assessment is understanding the context. An IP54-rated enclosure, suitable for a climate-controlled data center, is dangerously insufficient for an outdoor installation exposed to sandstorms and high-pressure washing.

The Human Element and Work Practices

Observing work practices is a crucial, often overlooked, part of identifying hazards. You need to see how both trained and untrained personnel work around live equipment.

Key things to watch for:

- Lockout/Tagout (LOTO) Procedures: Are they followed every time, or are there signs of shortcuts?

- Use of Personal Protective Equipment (PPE): Is the team using the correct arc-rated clothing and insulated tools?

- Operator Training and Awareness: Do employees know emergency shutdown procedures by heart?

This table breaks down common hazards encountered in the field.

| Common Electrical Hazards and Where to Find Them |

| :— | :— | :— |

| Hazard Type | Potential Location | Key Indicators for Inspection |

| Overloaded Circuits | MDBs, SMDBs, power outlets with multiple high-power appliances | Frequently tripping breakers, signs of overheating (discoloration, melting), buzzing sounds from panels. |

| Damaged Insulation | Exposed cables, wiring within machinery, high-traffic areas | Frayed or cracked wire jackets, exposed copper conductors, signs of physical damage. |

| Improper Grounding (Earthing) | Generators, portable equipment, IT server racks, building systems | Lack of a visible grounding conductor, high resistance readings, reports of minor shocks from equipment. |

| Corrosion | Outdoor enclosures, panels in humid or wash-down areas | Rust on enclosures, greenish/white powder on terminals, difficulty opening panel doors. |

| Unsafe Work Practices | Maintenance workshops, production floors, construction sites | Absence of LOTO locks on isolated equipment, incorrect or no PPE, using metal ladders near live parts. |

Recognizing these indicators early turns a standard check-up into a life-saving assessment.

Challenges in Regional Electrification

The need for robust electrical risk assessments is growing with regional development. While the UAE has achieved nearly universal electricity access, massive grid expansion continues. The International Energy Agency (IEA) highlights that bringing safe, reliable power to developing regions requires huge investment. In areas with less reliable power, informal connections and unsafe practices can create significant hazards that a formal assessment must rectify.

This systematic approach—blending technical inspection with environmental and human factors—gives you the complete picture of real risks, transforming the assessment into a powerful tool for preventing incidents.

How to Evaluate Risks and Prioritize Actions

After identifying potential electrical hazards, the next step is turning that list into a smart, actionable plan. An electrical risk assessment adds value by evaluating the impact of each hazard, allowing you to strategically protect your people and operations. This means focusing your budget and resources where they will make the biggest difference.

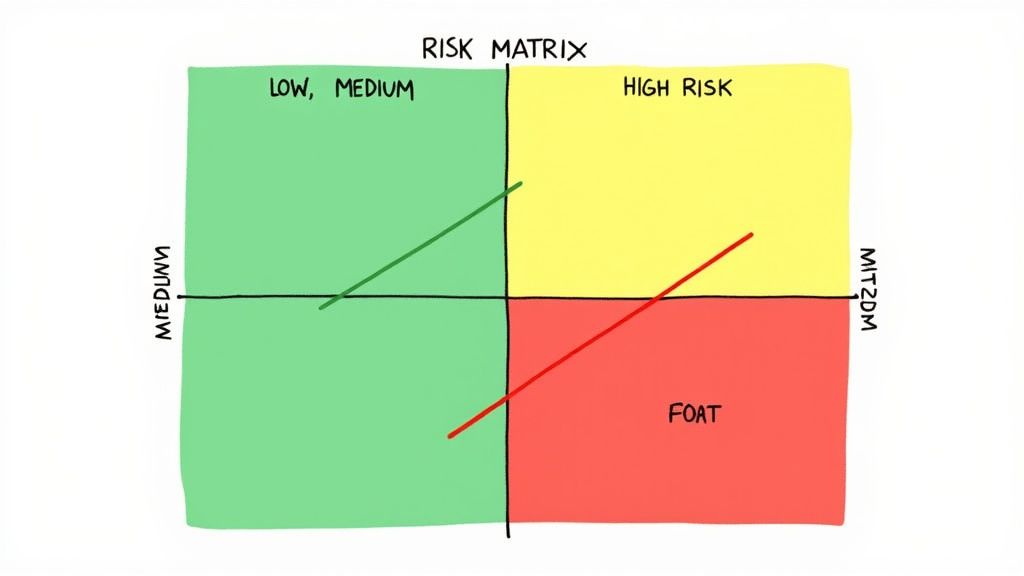

A risk matrix is the best tool for this job. It classifies each hazard by asking two questions: How likely is this to go wrong? And how bad would it be if it did? By plotting Likelihood against Severity, you assign a clear risk score to every issue.

Understanding the Risk Matrix

A risk matrix visually ranks dangers, moving you from a gut feeling of "that looks dangerous" to an objective conclusion like "this is a critical-priority risk." It uses two axes:

- Likelihood: The probability that a hazard will cause an incident. Is failure imminent or a one-in-a-million chance?

- Severity: The worst-case outcome if an incident occurs. Is it a minor injury or a fatality with a facility-wide shutdown?

Combining these allows you to categorize risks as Low, Medium, High, or Critical. This scoring system is invaluable for facility managers and procurement teams in the UAE who must justify budgets and schedule maintenance effectively.

Applying the Matrix with Local Context

Let's walk through two real-world GCC scenarios where the local environment is key to an accurate evaluation.

Scenario 1: Coastal Industrial Facility

- Hazard: An older outdoor switchgear unit at a plant near the coast in Sharjah shows visible corrosion on busbar connections and a cracked door gasket.

- Likelihood: High. The combination of salty, humid air and a compromised enclosure makes a short circuit or arc flash highly probable.

- Severity: Critical. An arc flash in the main switchgear could cause a major fire, life-threatening injuries, and take the facility offline for weeks.

- Risk Score: Critical. This requires immediate, top-priority action.

Scenario 2: New Climate-Controlled Facility

- Hazard: A minor scuff mark on the outer plastic casing of a cable tray inside a new Dubai data center.

- Likelihood: Very Low. The cable insulation is intact, the environment is clean and dry, and there is no foot traffic. The chance of this cosmetic issue causing an electrical incident is incredibly small.

- Severity: Low. If an issue did develop, it would likely be isolated to a single, non-critical circuit with minimal operational impact and almost zero chance of injury.

- Risk Score: Low. Document the issue and schedule a repair during the next planned maintenance window.

A common mistake is evaluating hazards in a vacuum. A loose terminal connection carries a different risk score inside a hot, high-vibration pump station compared to a clean commercial office. Context is king.

This systematic evaluation is the core of a professional electrical risk assessment. It transforms your field notes into a clear, defensible priority list, bridging the gap between finding a problem and implementing the right solution.

Implementing Controls That Actually Work

After identifying risks, the real work is implementing effective controls. A solid electrical risk assessment is about practical, robust solutions. For engineers and facility managers in the UAE and GCC, this means selecting controls that can handle our demanding climate and work practices.

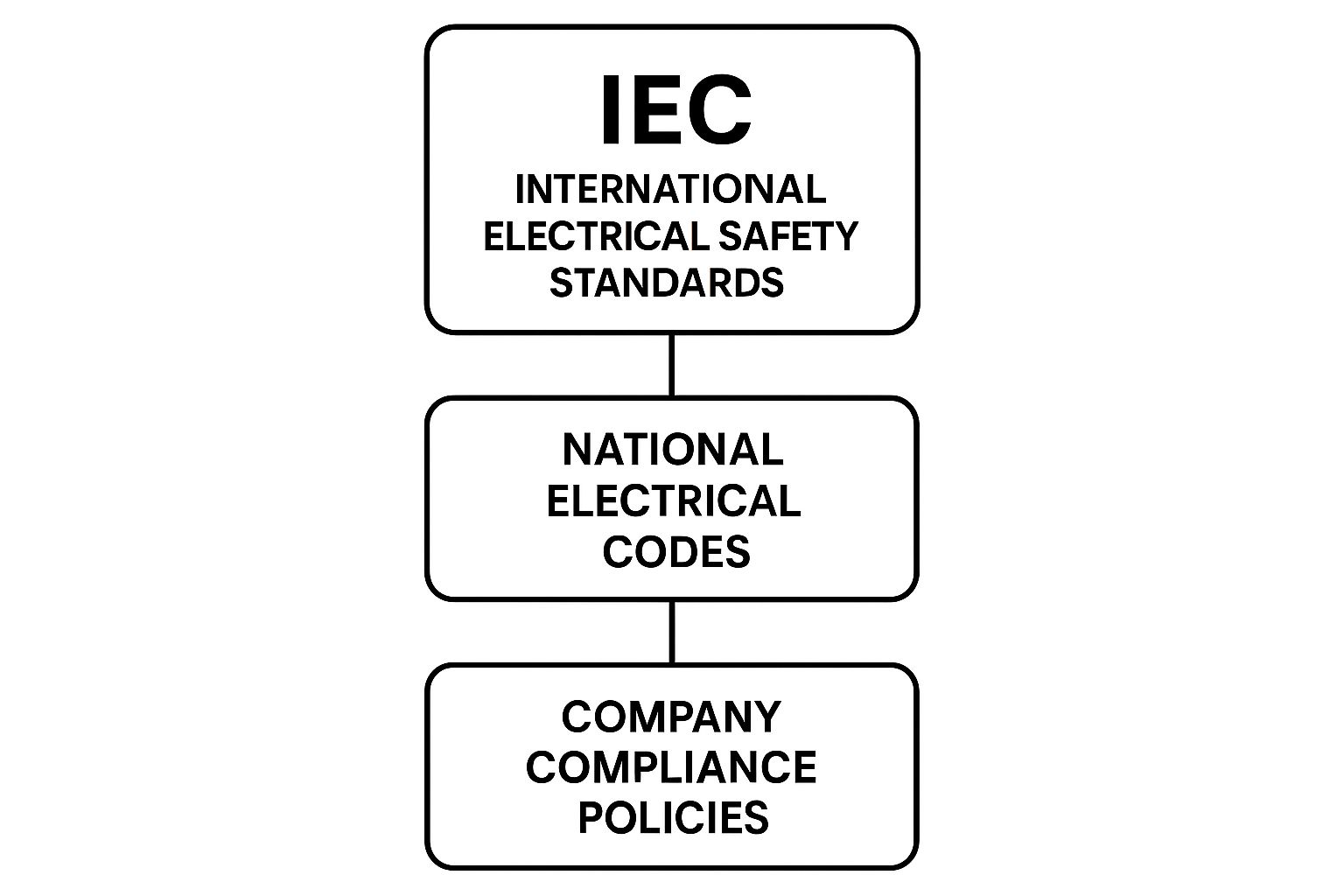

The hierarchy of controls is a proven framework that prioritizes the most effective, permanent fixes over weaker, temporary ones. It’s about engineering safety into the core of your system.

Engineering Controls: Your First Line of Defense

Engineering controls are physical, built-in changes to equipment that eliminate the hazard at its source. For any project in Dubai or Abu Dhabi, smart procurement and component selection are your primary tools for risk mitigation.

Here's what this looks like on the ground:

- Specifying High-Quality Circuit Protection: This is fundamental. For specialized applications, this might mean selecting ATEX compliant electrical components for hazardous areas. For everyday systems, it means picking breakers with the correct breaking capacity and trip settings. For instance, a quality DIN rail isolator ensures safe disconnection for maintenance.

- Selecting Correctly Rated Enclosures: In a region defined by heat, humidity, and dust, an enclosure is an environmental shield. Specifying panels with a high IP rating (IP65 or higher) is a non-negotiable control to prevent dust and moisture ingress.

- Arc Flash Mitigation Technology: Modern switchgear can include features like faster-acting breakers or arc-resistant designs that channel blast energy away from people. Investing in this technology is a direct and powerful control measure.

This is why a detailed electrical risk assessment must inform your procurement strategy. The findings should guide your team to select the right electrical protection equipment designed for the specific risks you've uncovered.

Administrative Controls: Guiding Safe Work

While engineering controls change hardware, administrative controls change how people interact with it. These are your procedures, training programs, and policies that promote safe behaviors.

Effective administrative controls in the GCC include:

- Rock-Solid Lockout/Tagout (LOTO) Procedures: A well-documented and strictly enforced LOTO program is the backbone of safe electrical maintenance.

- Specialized Training: Electricians need targeted training on the hazards they face, including arc flash awareness, safe testing methods, and recognizing early warning signs of equipment failure.

- Clear Safety Signage: Warning labels on panels stating arc flash boundaries, shock risks, and required PPE serve as constant reminders.

Hierarchy of Controls for Electrical Risk Mitigation

| Control Level | Description | Practical Example in an Electrical Context |

|---|---|---|

| Elimination | Physically remove the hazard. The most effective control. | De-energizing equipment completely before work begins (LOTO). |

| Substitution | Replace the hazard with something less hazardous. | Using a lower-voltage system (e.g., 24V DC) for control circuits instead of 230V AC. |

| Engineering | Isolate people from the hazard with physical changes. | Installing arc-resistant switchgear or using insulated tools. |

| Administrative | Change the way people work through procedures and training. | Implementing safe work permits, conducting arc flash training, and posting warning signs. |

| PPE | Protect the worker with Personal Protective Equipment. The last line of defense. | Requiring arc-rated clothing, insulated gloves, and face shields. |

This table shows that while PPE is necessary, it should never be your first solution. Real safety starts at the top of the hierarchy.

As the diagram shows, effective company policy must be built on the foundation of national codes and international standards. Applying this layered approach moves you from a reactive to a proactive safety culture, transforming an electrical risk assessment into real-world protection.

Common Questions on UAE Electrical Assessments

Even with a solid plan, questions arise during an electrical risk assessment in the UAE. The unique GCC environment—heat, humidity, rapid construction—often requires more than a standard, by-the-book approach.

Here are some common questions from engineers, facility managers, and electricians.

How Often Should an Electrical Risk Assessment Be Done?

The frequency depends on the facility's risk level. You must match your vigilance to your environment.

For high-risk industrial sites like manufacturing plants in Jebel Ali or outdoor installations, an annual comprehensive assessment is a non-negotiable best practice.

For lower-risk environments like commercial office towers or climate-controlled retail spaces, a deep-dive assessment every 3 to 5 years can be sufficient.

The most critical rule is to treat your electrical risk assessment as a living document. It's not a "set it and forget it" exercise. A new assessment is mandatory after any major system change, electrical incident, or when authorities like DEWA, ADDC, or SEWA issue new regulations.

This keeps your safety protocols relevant and effective against real-world conditions.

What Are the Most Overlooked Hazards in the GCC?

Professionals in the energy meter GCC market and beyond need a sharp eye for risks amplified by our climate and project dynamics. These hazards are most often missed:

- Solar Heat Gain on Enclosures: An outdoor panel in 45°C ambient heat can get much hotter in direct sunlight. If this "solar gain" wasn't factored into the design, breakers may trip, or electronics will fail prematurely.

- Accelerated Corrosion: The combination of high humidity and salty air, especially along the coasts of Dubai and Abu Dhabi, causes corrosion. Terminals that look fine can be corroded underneath, creating high-resistance hot spots—a serious fire hazard.

- Non-Compliant and Counterfeit Parts: Tight deadlines and budgets can make non-certified or counterfeit electrical components UAE suppliers might push seem tempting. These parts often fail catastrophically under load.

- Inadequate Temporary Power Setups: On construction sites, temporary power is often an afterthought, leading to poorly protected cables, shoddy grounding, and unsafe connections.

Who Is Qualified to Perform an Electrical Assessment?

An effective electrical risk assessment demands a team effort with a mix of expertise.

The leader should be a certified electrical engineer or a master electrician with hands-on experience in UAE regulations. They need support from:

- Facility Managers: They know the site's operational history and equipment quirks.

- Certified Safety Officers (NEBOSH/IOSH): They align the assessment with the facility's wider health and safety system.

- On-the-Ground Technicians: They spot subtle signs of trouble that an outsider might miss.

For high-risk industrial facilities, a specialized third-party consultant provides an unbiased set of fresh eyes. This collaborative approach leads to a truly useful assessment that boosts safety and reliability. Part of this involves specifying the right protective devices. To learn more, check our guide on electrical surge protection.

For expert support on your next project in the UAE, reach out to our Dubai team. We provide the technical guidance and high-quality components you need to build safer, more resilient electrical systems. Contact us for project support in Dubai and across the GCC.

Leave a Reply