A Guide to Choosing the Right Earth Resistance Test Meter in the UAE

An earth resistance test meter is a specialized tool designed to measure the resistance of an earthing system—a health check for the most critical safety feature of any electrical installation. For engineers, panel builders, and electricians across the UAE and GCC, this measurement provides the critical data needed to confirm a safe, low-resistance path to ground, which is the first line of defence against electric shock, equipment damage, and costly downtime.

Why Grounding Integrity is a Must in the UAE's Climate

In the fast-paced world of UAE infrastructure, from Dubai’s soaring skyscrapers to Abu Dhabi’s sprawling industrial hubs, electrical safety cannot be left to chance. A solid grounding system is the backbone of this safety, but it must be tested and verified to ensure performance. This is where an earth resistance test meter becomes an indispensable tool for any serious electrical professional, ensuring compliance with local utility regulations and international standards.

A dependable, low-resistance path to the earth acts as a safety valve. When a fault occurs, it instantly diverts dangerous currents away from people and sensitive equipment, channelling them harmlessly into the ground.

The Fundamental Role of Earthing in Electrical Safety

Without a proven, low-resistance path, a simple electrical fault could spiral into a disaster. A properly functioning earthing system is non-negotiable for several reasons:

- Protecting People: It stops the metal casings of equipment from becoming live during a fault, which drastically reduces the risk of severe electric shock.

- Preventing Equipment Damage: By providing fault currents with an easy path, it helps trip protective devices like circuit breakers almost instantly, preventing expensive damage to machinery and electronics. This is a core component of any effective energy management solution in Dubai.

- Avoiding Fires: Good grounding minimises the chance of arcing and overheating—two of the most common culprits behind electrical fires in commercial and industrial buildings.

The Financial and Regulatory Imperative

The critical nature of proper grounding is underscored by the region's increasing investment in electrical safety infrastructure. Here in the United Arab Emirates (UAE), strict regulations from bodies like DEWA and ADDC make earth resistance testing a mandatory step. The ground resistance testing market in the Middle East and Africa was valued at around USD 120 million, a figure that speaks volumes about the vital role these instruments play in a booming construction sector.

An earth resistance test meter isn't just a diagnostic tool. It's your primary method for ensuring compliance, protecting valuable assets, and saving lives. In a region with unique environmental hurdles like high soil resistivity from sandy, dry conditions, regular and accurate testing is essential for upholding safety standards.

Decoding the Science of Earth Resistance

Think of your earthing system as the safety net for your entire electrical setup. If something goes wrong, this system needs to offer a clear path for dangerous currents to flow into the ground. Getting this right is fundamental to safety, especially in the unique environmental conditions seen across the UAE and the wider GCC region.

We are measuring earth resistance—how much the soil pushes back against the flow of electricity. This is a direct indicator of how well your grounding system can protect people and equipment. A low resistance value means fault currents can vanish quickly. A high value is a hidden danger. An earth resistance test meter provides a hard number, telling you precisely whether your system is a reliable safety net or a risk waiting to happen.

Key Factors Influencing Earth Resistance in the GCC

Achieving low earth resistance in the UAE and Saudi Arabia can be a real challenge due to climate and environmental factors like heat, humidity, and dust.

- Soil Composition: Much of the soil here is sandy or rocky, which has a naturally high resistivity. The large air gaps between sand particles make it tough for electricity to find a smooth, conductive path.

- Moisture Content: Water is a fantastic conductor. In our arid climate, soil moisture is consistently low, which sends resistance values soaring. A system might test perfectly after a rare downpour but perform poorly during the long, dry summer months.

- Temperature: The extreme ground temperatures we experience daily in Dubai bake the moisture out of the soil around the earth electrodes. This drying effect pushes resistance even higher, weakening the system's effectiveness.

- Chemical Composition: Salts and minerals in the soil can help lower resistivity. However, these levels can change over time, which is why regular testing with a reliable energy meter in the GCC region is non-negotiable.

At its core, the principle is straightforward: the easier the path for electricity to travel through the soil, the lower the resistance and the safer the installation. Your earth resistance test meter is the only reliable way to confirm that this path is truly clear and effective.

How Electrodes Create a Safe Discharge Path

An earthing system is a network of components working together. The star player is the earthing electrode—usually a copper-clad rod driven deep into the earth. Its job is to create maximum surface area contact with the soil, establishing a solid, reliable connection.

This is precisely what your earth resistance test meter measures. It sends a controlled current through the electrode, measures the voltage drop, and uses Ohm's Law (R = V/I) to calculate the resistance. This powerful test gives you the data needed to protect people, prevent equipment damage, and meet local and international standards like those from the IEC and GCC. Without this verification, your grounding system is just an assumption.

Choosing Your Earth Resistance Testing Method

Picking the right testing method depends on the job—a new installation on a Dubai construction site or a routine check in a crowded Abu Dhabi industrial park. Using the wrong method can give you dangerously misleading numbers. For professionals working in the GCC, understanding the practical differences between these techniques is non-negotiable for guaranteeing the integrity of a grounding system.

The 3-Pole Fall-of-Potential Test for New Installations

The 3-Pole Fall-of-Potential method is the gold standard for testing newly installed earthing electrodes. It's the most trusted way to get a solid baseline measurement before an electrical system goes live, perfect for open areas where you have room to drive temporary test stakes.

Here's how it works: you inject a known current through the main earth electrode and a temporary current stake (C2). A second temporary potential stake (P2) is moved at different distances between them to measure the voltage drop. The true earth electrode resistance is found when the reading levels off, hitting a "plateau."

The secret to a good Fall-of-Potential test is stake placement. The temporary stakes must be positioned outside the electrical "sphere of influence" of the main earth electrode and each other to avoid interference and a bad reading.

The 4-Pole Method for Soil Resistivity Surveys

Before construction begins on large-scale projects, you need to understand the site's conditions. The 4-Pole method, or Wenner method, is used for measuring soil resistivity. This data is essential for engineers to design an effective and economical earthing system from the start.

This technique uses four equally spaced stakes. The earth resistance test meter sends a current between the two outer stakes and measures the voltage potential between the two inner ones. By taking readings at different stake spacings, engineers can determine resistivity at various depths, which is critical for the unique geological layers found across the UAE.

A solid grasp of soil resistivity helps with:

- Optimal Electrode Design: Determining the right length and number of earth rods.

- Site Selection: Pinpointing the best location for the earthing system.

- Cost-Effective Solutions: Designing a system that meets safety standards without over-engineering.

As the table shows, the bigger the potential fault current, the lower the earth resistance needs to be to maintain safety.

The Clamp-On (Stakeless) Method for Maintenance

In dense urban areas or inside facilities where driving stakes is not an option, the clamp-on (or stakeless) method is a lifesaver. It’s designed for checking existing earthing systems that are already part of a parallel or looped network, making it perfect for quick, routine maintenance.

This method uses two clamps around the earth conductor. One creates a known voltage, and the other measures the current flowing through that loop. The meter calculates the resistance for that section without disconnecting any wires. It's fast and convenient, but it only works on parallel grounding systems. For a deeper dive into your system's health, including harmonics and power factor, learn more about our advanced power quality meter solutions.

How to Select the Right Earth Resistance Test Meter

Selecting an earth resistance test meter is an investment in safety and compliance. For engineers and technicians in the UAE and GCC, the right choice must account for our unique challenges. A meter that works in a mild climate might struggle in the dense electrical noise of downtown Dubai or the demanding conditions of a Saudi industrial site. Choosing a tough, accurate instrument from a trusted supplier of electrical components in the UAE like GoSwitchgear ensures performance you can count on.

Core Technical Specifications to Evaluate

First, nail the fundamentals. These core specs are the foundation of any reliable testing process.

- Measurement Range and Resolution: Does the meter's resistance range cover your needs? A wide range, like 0.01 Ω to 2000 Ω, offers versatility. For sensitive data centres, a high resolution of 0.01 Ω is non-negotiable.

- Test Current: The meter needs enough power to generate a test current that can cut through background noise, especially in substations. A higher current generally provides a more stable reading.

- Operating Temperature Range: With the extreme heat in the GCC, a wide operating temperature range is a must. Look for meters rated to perform accurately in ambient temperatures up to 50°C or higher.

Critical Features for the GCC Environment

Once the basics are covered, other features become essential for accurate results in the UAE and KSA.

A key feature is noise rejection. Urban and industrial zones are flooded with electrical interference. A quality earth resistance test meter must have solid filtering or an Automatic Frequency Control (AFC) function. AFC intelligently detects ambient noise frequencies and chooses a different test frequency to ensure measurements are not skewed.

Another critical factor is the IP (Ingress Protection) rating. A meter with at least an IP54 rating is built to handle the dust and humidity common on construction sites and coastal areas in the region. This is a necessity, not a luxury.

Advanced Functions That Enhance Productivity

Modern meters do more than just measure; they boost efficiency and help meet strict regulatory demands.

- Data Storage and Logging: The ability to save hundreds of test results directly on the device is a massive time-saver.

- USB or Bluetooth Connectivity: Easily transfer saved data to a PC for generating professional test reports for clients and regulatory bodies.

- Multi-Function Capabilities: Advanced models can handle 3-pole and 4-pole tests, measure soil resistivity, and check AC/DC voltage. This versatility means carrying one tool for several jobs.

The market for advanced tools is growing, pushed by demand in the UAE and neighbouring GCC countries. Industries like oil and gas, mining, and manufacturing follow strict grounding safety standards, making these meters essential. You can explore a detailed market analysis on these trends.

Safety First: Understanding CAT Ratings

Do not overlook the safety rating. A CAT IV 600V or CAT III 1000V rating is critical when working on utility-level or high-energy industrial systems. This rating guarantees the meter can handle sudden voltage spikes, protecting you and the instrument.

By weighing these technical specs, environmental protections, and productivity features, you can confidently choose an earth resistance test meter perfectly matched to the challenges of the UAE's electrical industry.

Performing a Fall-of-Potential Test Step by Step

The 3-Pole Fall-of-Potential test is the definitive method for verifying a new earthing system. This walkthrough covers the process step-by-step, ensuring you can generate accurate, repeatable data that meets the strict project standards across the UAE.

Step 1: Initial Safety Checks and Preparation

Safety always comes first. The absolute first step is to ensure the earthing system is completely disconnected from the building's electrical supply to prevent electric shock and protect your test equipment.

Best Practices Checklist:

- Isolate the System: Use proper lockout/tagout procedures to confirm the earth electrode is isolated.

- Inspect Your Equipment: Check your earth resistance test meter, leads, and stakes for damage. Ensure the meter has a full battery.

- Prepare the Stakes: You need two auxiliary stakes: one for current injection (C2) and another for potential measurement (P2). Drive them firmly into the ground for solid electrical contact.

Step 2: Correct Placement of Auxiliary Stakes

The accuracy of your test depends on where you place the stakes. The most common mistake is placing them too close to the main earth electrode, inside its "sphere of influence," which results in overlapping resistance areas and false readings.

A good rule of thumb is to place the current stake (C2) a significant distance away—at least 10 times the length of the earth rod. For a 3-meter rod, place C2 at least 30 meters out. The potential stake (P2) then goes on the straight line between the electrode (E) and C2, ideally at 62% of the total distance from E to C2.

Pro Tip: Keep everything in a straight line and away from buried metal like pipes or cables, as they can interfere with your measurement and skew the results.

Step 3: Connecting the Meter and Taking Readings

With your stakes set, connect the earth resistance test meter. The terminals are typically color-coded to make it foolproof.

- The E terminal connects to the main earth electrode.

- The P terminal connects to the potential stake (P2).

- The C terminal connects to the outer current stake (C2).

Once connected, press the test button and record the resistance value. A single reading is not enough for full verification.

Step 4: Verifying Accuracy with a Resistance Curve

To confirm your reading is accurate and outside the spheres of influence, create a simple resistance curve.

- Keep the C2 stake in its original position.

- Move the P2 stake 10% closer to the main electrode (E) and take a new reading.

- Move the P2 stake 10% farther away from its original spot (towards C2) and take a third reading.

If all three readings are nearly identical, you can trust that your original measurement at the 62% mark is reliable. This flat spot, or "plateau," confirms you've found the true earth resistance.

Newer tools like augmented reality for maintenance are changing the game, offering on-screen guides and automatic data logging to boost accuracy and report quality.

Navigating Local Compliance and Best Practices

Technical skill is only half the battle. For professionals in the UAE, ensuring every test meets local and international standards is what guarantees safety and project sign-off. Your earth resistance test meter is your key to generating the compliant reports that prove your work meets the demanding standards of Dubai and Abu Dhabi.

Adherence to standards from bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) is standard procedure in the GCC. These guidelines lay out the blueprint for safe electrical installations with specific requirements for grounding.

Meeting Regional Standards

The push for rigorous earth resistance testing in the UAE intensified with the country's massive infrastructure boom. As regulatory bodies like the Emirates Authority for Standardization and Metrology (ESMA) implemented stricter grounding rules, the fall-of-potential test became the standard for validation, especially in high-stakes facilities where earth resistance must be below 1 ohm. You can review grounding test requirements for critical sites to understand the history of these standards.

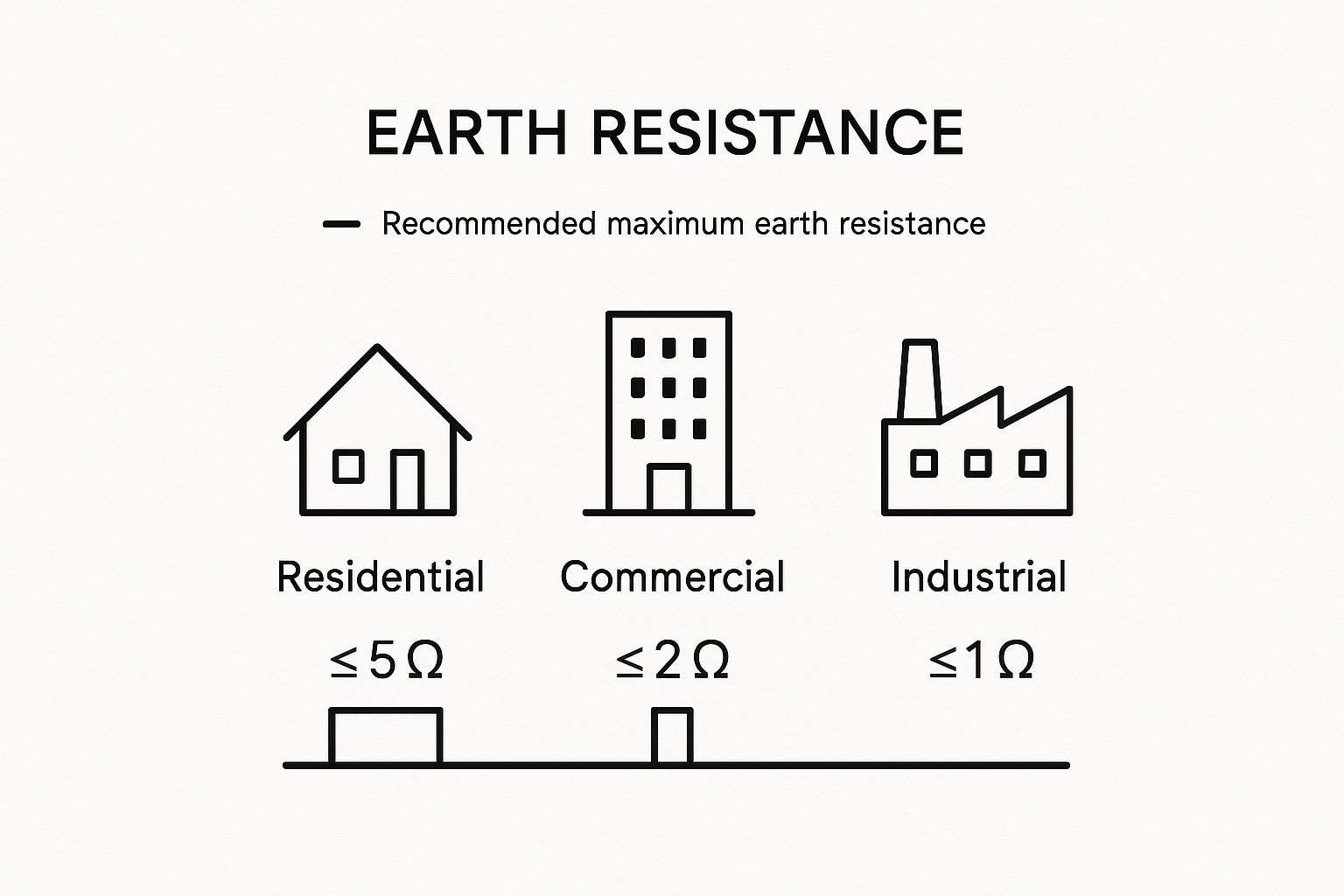

Common Resistance Targets in the UAE:

- Sensitive Electronic/Telecom Sites: Aim for 1-5 ohms or less to protect delicate equipment.

- Substations and Industrial Plants: The goal is often below 1 ohm due to massive potential fault currents.

- Standard Commercial/Residential Buildings: Values up to 5-10 ohms are often acceptable, but lower is always better.

The Importance of Periodic Testing and Record Keeping

In the GCC's harsh climate, a grounding system's performance can degrade over time due to soil drying and corrosion. This makes periodic testing a vital part of any preventive maintenance schedule. Regular checks, like testing RCDs, ensure the system remains effective. For more on overall safety, see our guide on how to properly test an RCD.

This is where modern digital earth resistance test meters with data logging capabilities truly shine. They allow technicians to easily store time-stamped results, building a detailed history of the system's health. This digital paper trail is invaluable during regulatory audits, client handovers, and troubleshooting.

Partnering for Electrical Safety in the UAE

Accurate earth resistance testing is the bedrock of electrical safety, asset protection, and regulatory compliance across the UAE. For any electrical professional in this demanding market, mastering these principles is essential.

Whether you're verifying a new installation in Dubai or running maintenance checks in Abu Dhabi, a high-quality earth resistance test meter is a non-negotiable part of your toolkit. It's the only way to get the hard data needed to prove a grounding system will perform during a fault. The unique environmental and regulatory hurdles in the GCC mean that only the most accurate and durable instruments are up to the task.

Your Local Partner in Compliance and Performance

Meeting the highest standards requires not just the right gear, but also expert support and continuous education. Sharpen your skills and stay ahead of regional requirements by exploring resources like our guides on professional electrical safety training.

Investing in dependable testing equipment is a direct investment in your project's success and professional reputation. It demonstrates a commitment to quality and safety that clients and regulatory bodies demand.

For practical advice on selecting the perfect earth resistance test meter for your next project, or for dedicated technical support, the GoSwitchgear team in Dubai is ready to help. We are committed to helping you meet and exceed the tough safety standards of the UAE and the broader GCC region.

Contact our Dubai team for project support and product enquiries. As your trusted partner for electrical components in the UAE, GoSwitchgear is here to help. Explore our full range of solutions at https://goswitchgear.com.

Leave a Reply