Accurate Cable Sizing in the UAE: A Guide for Engineers and Panel Builders

Using a proper cable size calculator is far more than a convenience; it is a critical risk management tool for any electrical project in the UAE and GCC. For engineers, panel builders, and procurement teams, it ensures every specified cable can safely handle its load without overheating or causing significant voltage drop, building a foundation of safety, performance, and compliance.

Why Accurate Cable Sizing is Critical in the UAE & GCC

Here in the United Arab Emirates and across the GCC, choosing the right electrical cable size isn’t just a technical detail—it’s a critical engineering decision that impacts operational safety, long-term reliability, and project budgets. The region’s unique climate introduces serious challenges that directly affect how a cable performs.

Engineers and electricians from Dubai to Abu Dhabi must contend with environmental conditions that can severely impair a cable’s current-carrying capacity. These factors are central to achieving a safe, compliant, and cost-effective design.

The Impact of Local Environmental Conditions

The primary challenge is the extreme ambient heat, with ground and air temperatures often soaring past 40°C. This intense heat significantly reduces a cable’s ability to dissipate its own thermal energy, forcing a reduction in its safe operating current. This is a crucial factor for any energy management solution Dubai relies on for efficiency.

Furthermore, high humidity and airborne dust present risks to terminations and enclosures. Specifying high IP-rated electrical components UAE standards demand is essential to prevent corrosion and connection failure, adding another layer of complexity to system design.

The Real-World Consequences of Miscalculation

An incorrect cable size calculation leads to two significant and costly problems.

- Undersized Cables: A cable too small for its load, especially in the UAE’s high ambient heat, will inevitably overheat. This thermal stress degrades insulation over time, creating a serious fire hazard and leading to premature failure. It also causes a significant voltage drop, impairing the performance of sensitive electronics and reducing overall system efficiency.

- Oversized Cables: While safer, oversizing cables leads to unnecessary material costs, which can escalate quickly on large-scale projects. Larger cables are also more difficult to install, requiring more space in conduits and trunking and complicating terminations within panels. This drives up labor costs and can disrupt tight project timelines.

A reliable cable size calculator is your best defense. It processes key variables—load, length, ambient temperature, and installation method—to provide a clear, data-driven recommendation that aligns with local utility regulations from bodies like DEWA and ADDC, ensuring compliance with IEC standards.

Ultimately, precise calculation ensures your project not only meets international standards like BS 7671 but is also engineered to withstand the specific environmental pressures of the GCC. It is a non-negotiable step for professionals committed to delivering safe, efficient, and reliable electrical systems.

For a dependable online tool, try the GoSwitchgear cable sizing tool for your next project.

Key Inputs for an Accurate Cable Calculation

Any cable size calculator is only as good as the data it receives. For projects in the UAE, accurate inputs are essential for a safe and compliant installation. This means going beyond basic load details to incorporate local environmental challenges.

The process begins with defining core electrical parameters. These foundational data points are non-negotiable for an accurate calculation.

- Load Current (Amperes): The total current the cable must handle, accounting for the full load and any high inrush currents from motors.

- Permissible Voltage Drop: Local standards, adhering to BS 7671, are strict: a maximum of 3% for lighting and 5% for other loads. Exceeding these limits leads to equipment underperformance and premature failure.

- Cable Length (Metres): The total distance from source to load, which directly impacts voltage drop.

- Conductor Material: The choice between copper and aluminum. Copper offers superior conductivity in a smaller size, while aluminum is lighter and more cost-effective for large feeder cables.

GCC-Specific Derating Factors: A Critical Consideration

This is where generic online calculators often fail and local expertise becomes vital. In the UAE and GCC, derating factors are not optional—they are a critical part of the equation that significantly reduces a cable’s real-world current-carrying capacity. Ignoring them is a common but costly mistake.

With major infrastructure projects across Dubai, Abu Dhabi, and KSA, compliance with BS 7671 and IEC 60364 is mandatory. A cable size calculator determines the correct cross-sectional area to manage the load and voltage drop. While calculations often start with a 0.8 power factor and 230V/415V systems, the UAE’s ambient temperatures demand significant derating. This often requires specifying larger, armored cables to prevent overheating and potential energy losses of up to 15%. You can explore some of these technical details on Eland Cables’ platform to see how these factors interact.

Forgetting to apply derating factors is like planning a desert journey without accounting for the heat. The system might work initially, but it’s destined for an early and costly failure.

For any project in the GCC, these are the key derating factors you cannot ignore:

- High Ambient Temperature: Searing air and ground temperatures severely limit a cable’s ability to cool down, a major challenge for any energy meter GCC installation.

- Cable Grouping: Bundling multiple cables in a tray or trunking traps heat, requiring each cable’s capacity to be reduced.

- Installation Method: The installation method—conduit, direct burial, or open tray—dramatically affects thermal performance.

By meticulously gathering this data, procurement teams and panel builders can ensure every specification is optimized for its application and environment, avoiding expensive errors and building systems that last.

A Practical Walkthrough of a Cable Size Calculator

Theory is one thing, but confidence comes from practical application. Let’s walk through a real-world scenario common in the UAE electrical sector: sizing a feeder cable for a Sub-Main Distribution Board (SMDB) in a new commercial tower in Dubai.

This example will demonstrate how a cable size calculator translates project data into a safe, compliant specification. The goal is to understand the why behind the result, clarifying how tools like the GoSwitchgear cable sizing tool process your inputs for critical projects.

Setting the Scene: The Commercial Tower SMDB

As the engineer, you must specify the 4-core armored cable (XLPE/SWA/PVC) running from the Main Distribution Board (MDB) to an SMDB on the tenth floor. This board will power a typical mix of office lighting, general-purpose outlets, and a small HVAC unit.

Here is the key data gathered from site plans:

- System Voltage: 415V, Three-Phase—standard for commercial power distribution in Dubai.

- Total Connected Load: The SMDB is designed for a calculated load of 125 Amperes (A).

- Cable Run Length: The measured route from the MDB room, up the service riser, to the SMDB cabinet is 75 meters.

- Installation Method: The cable will be installed on a perforated cable tray alongside six other similarly sized cables. This grouping is a crucial detail.

How to Install: From Raw Data to a Real-World Answer

With this information, you use your cable size calculator. You input the basics: 125A load, 75m length, and a 415V three-phase system. The calculator might initially suggest a size based only on current-carrying capacity. However, the next step is critical for a UAE installation.

You must apply the non-negotiable derating factors:

- Ambient Temperature (Ca): The service riser in a Dubai tower gets hot. We apply a derating factor for an ambient temperature of at least 45°C.

- Grouping (Cg): With our cable grouped with six others on a tray, heat dissipation is reduced. A grouping factor is essential.

After entering these derating factors, the calculator re-evaluates. The initial cable size is no longer sufficient. The tool automatically selects a larger cross-sectional area to ensure the cable can safely handle the 125A load under real-world conditions.

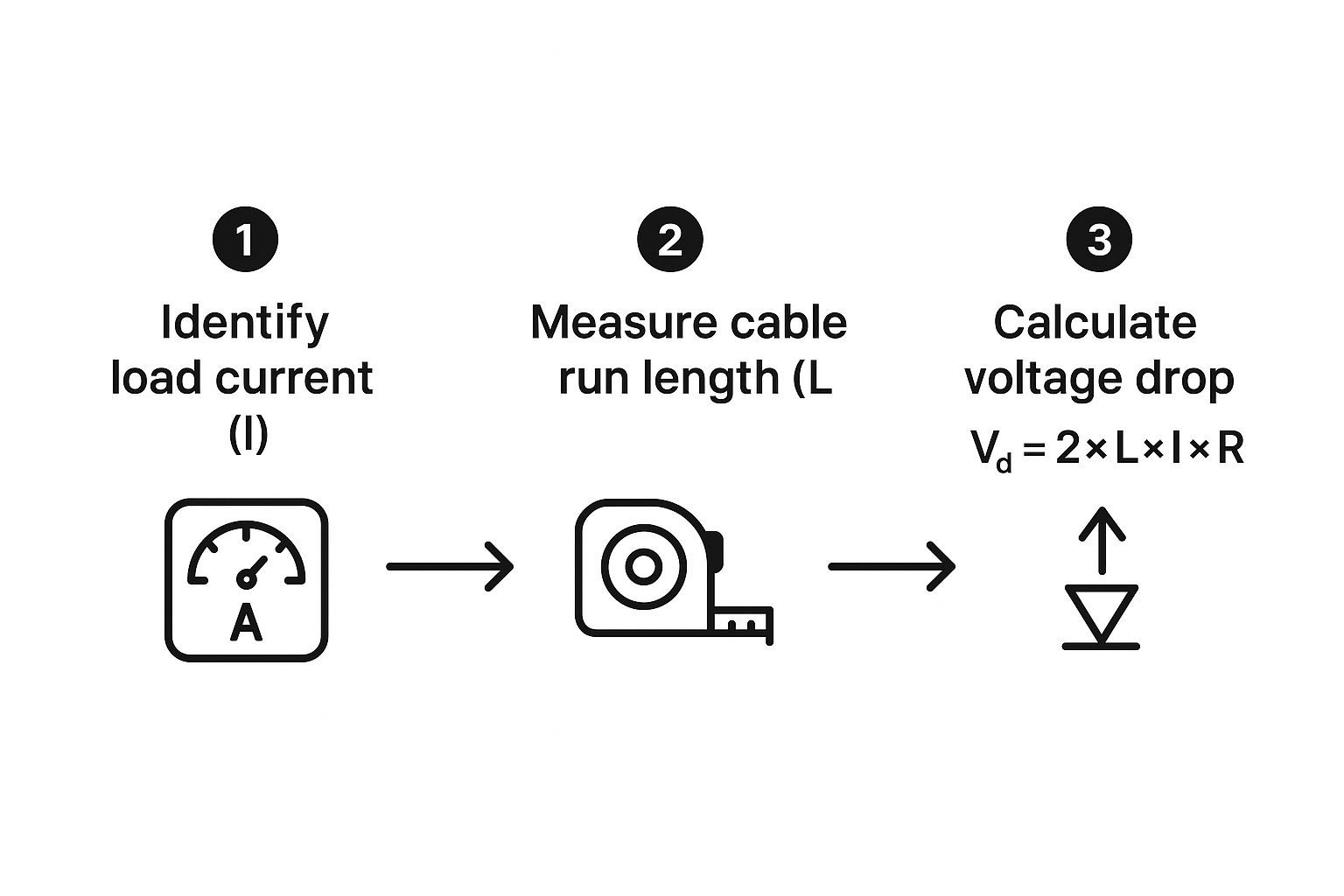

This infographic breaks down the voltage drop calculation, another key check performed by the calculator.

As shown, the load current, cable length, and the cable’s resistance all contribute to the final voltage drop percentage. A longer cable or a higher load will increase the drop.

This process demonstrates that the calculator is not a black box but a logic engine applying BS 7671 principles and local regulations. It saves time on manual calculations and prevents dangerous assumptions, enforcing a systematic approach.

Finally, the calculator confirms that the new, larger cable size keeps the voltage drop well within the 5% limit mandated by DEWA for power loads. The result is a specification that is safe, compliant, and reliable for the project’s entire lifecycle.

Cable Derating Factors for GCC Ambient Temperatures

This table provides standard derating factors for PVC and XLPE insulated cables, which are critical inputs for any cable size calculation in the high ambient temperatures of the GCC.

| Ambient Temperature (°C) | Derating Factor for PVC Insulated Cables | Derating Factor for XLPE Insulated Cables |

|---|---|---|

| 35 | 0.94 | 0.96 |

| 40 | 0.87 | 0.91 |

| 45 | 0.79 | 0.87 |

| 50 | 0.71 | 0.82 |

| 55 | 0.61 | 0.76 |

For our Dubai tower example at 45°C, an XLPE cable is considered to have only 87% of its standard current-carrying capacity. This illustrates why applying the correct derating factor is a fundamental step in professional and safe cable sizing.

How to Calculate and Manage Voltage Drop

An electrical system can appear perfectly designed yet fail under load due to an invisible saboteur: voltage drop. In the UAE’s demanding electrical landscape, excessive voltage drop is a direct threat to equipment and operational stability, causing lights to flicker, motors to struggle, and electronics to fail prematurely.

Local standards, aligned with BS 7671, set clear limits. The maximum permissible voltage drop is 3% for lighting circuits and 5% for all other loads. Adherence is non-negotiable for system integrity.

The Core of the Calculation

Every cable size calculator uses a fundamental formula based on the mV/A/m (millivolts per ampere per metre) value found on manufacturer datasheets. This value specifies the voltage lost for every amp of current over one meter of cable.

The calculation is straightforward:

Voltage Drop (Vd) = (mV/A/m) x Load Current (I) x Cable Length (L) / 1000

This formula allows engineers to quickly verify if a proposed cable size meets the 3% or 5% threshold.

Knowing this formula provides a data-backed justification for specifying a larger, more expensive cable. It demonstrates that the choice is essential for regulatory compliance and long-term system reliability.

Practical Mitigation Strategies and Best Practices

If your calculation reveals an unacceptable voltage drop, you have several practical options.

- Increase Cable Size: The most effective solution is to increase the cable’s cross-sectional area (mm²). A thicker conductor has lower resistance, directly reducing voltage loss.

- Optimize Cable Routes: Shortening the total cable length can significantly cut voltage drop. Even a few meters can make a crucial difference.

- Divide the Load: If feasible, split a single large load into smaller circuits fed by separate, shorter cables. This reduces both the current and length for any single run.

- Boost Source Voltage: For long-distance industrial applications, use transformers to step up the voltage for transmission and step it down at the point of use.

Managing voltage drop is also critical in mobile setups. For example, a deep cycle marine battery guide often emphasizes how cable length and current draw affect system performance. Mastering these principles ensures every GCC installation is stable, safe, and efficient.

Common Installation Mistakes & How to Avoid Them

Even seasoned professionals can fall into common traps when specifying cables. Learning from these frequent errors is faster and cheaper than discovering them on-site. Using a reliable cable size calculator is the best defense, but knowing what pitfalls to avoid is equally important.

Relying on outdated ‘rules of thumb’ is a dangerous habit. A guideline from a decade ago is inadequate for today’s complex installations, especially given specific regulatory and environmental demands. Every project in Dubai or the wider GCC requires a fresh calculation based on current data and standards.

Overlooking Harmonics from Modern Loads

A frequent and significant error is sizing a cable based only on its fundamental load current while ignoring the impact of modern electronics like Variable Frequency Drives (VFDs) and LED lighting. These non-linear loads introduce harmonic currents that generate heat in the neutral conductor but perform no useful work, leading to overheating and premature failure if not accounted for. Whether it’s a DIN rail isolator or an SMPS power supply, considering the full electrical profile is essential.

Forgetting harmonics is like ignoring an unseen passenger in a car—they still add weight and strain the engine. You must account for this additional thermal load, especially in commercial and industrial settings.

Misapplying Derating Factors

Incorrect application of derating factors is a massive issue in the UAE’s climate. It is not enough to know that derating is needed; factors must be applied correctly and cumulatively.

Common installation mistakes include:

- Grouping: Applying a derating factor for three cables when seven are in the trunking. The increased heat buildup will render the cable undersized.

- Burial Depth & Soil Resistivity: Forgetting that deeper burial or dry, sandy soil (with poor thermal conductivity) restricts heat dissipation. This is a crucial consideration for underground installations across the GCC.

- Combined Factors: An engineer might apply a temperature derating factor but forget the grouping factor, or vice versa. All applicable factors must be multiplied for an accurate result.

For instance, this screenshot from Schneider Electric’s EcoStruxure Power Design software shows the level of detail required for accurate calculations, forcing users to factor in everything from installation methods to network characteristics.

The software’s interface highlights how multiple parameters are integrated to ensure a holistic, safe design. A motor failing to start or a breaker tripping due to heat are classic symptoms of miscalculation. Using a robust tool prevents these costly and disruptive field issues.

Conclusion: Partner with GoSwitchgear for Project Success

For any project in Dubai, Abu Dhabi, or across the region, getting your calculations spot-on is everything. Accurate cable sizing is fundamental to creating a safe, efficient, and compliant electrical system that can withstand the unique challenges of the GCC climate. From selecting the right electrical components UAE projects require to ensuring every calculation accounts for local derating factors, precision is key.

The team at GoSwitchgear is here to supply the compliant components and technical support you need to meet local standards every time. For expert guidance on your projects in Dubai and across the GCC, reach out to our team for project support.

Explore our full range of cables and accessories at GoSwitchgear.

Leave a Reply