A Practical Guide to Selecting the Right Cable Lug Dimensions in the UAE

For any engineer, panel builder, or electrician working in the UAE and wider GCC, selecting the right component isn't just a matter of preference—it's critical for safe, compliant electrical terminations. When we talk about cable lug dimensions, three measurements matter most: the cable entry size (mm²), the stud hole diameter for the bolt, and the barrel length. In our region's demanding climate, precision is everything.

Understanding Essential Cable Lug Dimensions

Incorrect sizing can lead to overheating, connection failure, and serious safety hazards, especially in the high-temperature environments common across the GCC. A solid grasp of dimensional standards is fundamental for any electrical professional. These three key measurements work together to guarantee both mechanical strength and electrical integrity.

Think of them as the three pillars of a perfect termination:

- Cable Entry Size: Must perfectly match the cable's cross-sectional area (e.g., 95mm²) to ensure a snug fit before crimping.

- Stud Hole Diameter: Must align exactly with the terminal bolt or stud (e.g., M8, M10) for a tight, low-resistance connection.

- Barrel Length: Must be sufficient for the crimping tool to create a durable, reliable termination that withstands mechanical stress and environmental factors.

Here in the UAE, material choice also plays a big part in sizing. In the local market for electrical components, copper is dominant, holding an estimated share of over 60% due to its superior conductivity and ability to meet strict local standards.

These standards are clear: lug sizes, which typically range from 1.5 mm² to 300 mm², must match the cable dimensions precisely. This isn't just a recommendation; it's a requirement to guarantee optimal connectivity and prevent failures. For a deeper look at the electrical components market, you can find insights from recent industry analysis. Mastering these basics provides the confidence to select the right components for any project in Dubai or Abu Dhabi.

How to Interpret Cable Lug Dimension Charts

At first glance, technical datasheets for electrical parts can seem complex. However, once you know what to look for, reading cable lug dimension charts is straightforward and essential for accurate project specification.

For engineers and procurement teams in Dubai and Abu Dhabi, these charts are indispensable tools for ensuring the correct component is selected for the job, preventing costly errors and project delays.

Decoding Key Abbreviations

Manufacturers use a standard set of abbreviations to define each critical measurement on a lug. Familiarity with these is the first step to confident specification:

- CSA (mm²): Cable Cross-Sectional Area. This spec matches the lug to the conductor size.

- d2 (mm): The stud hole diameter. It must correspond to the size of the terminal bolt (e.g., M10 or M12).

- B (mm): The palm width. This is a critical measurement for ensuring proper spacing and clearance when mounting lugs on a busbar.

- L (mm): The overall length of the lug from end to end.

- I (mm): The barrel length, a crucial dimension for achieving a secure, full-contact crimp.

Let's walk through a practical example. Suppose you need to terminate a 95mm² cable onto a terminal using an M12 bolt. You would start by finding the 95mm² CSA row on the chart. Then, scan across that row to find a lug with a d2 dimension of approximately 13mm to accommodate the M12 bolt.

By mastering these simple cross-referencing steps, procurement teams and engineers can drastically reduce ordering mistakes and avoid costly project delays. Choosing the right electrical components UAE suppliers offer is the first step toward a compliant and reliable termination.

For a full lineup of high-quality components for your projects in the UAE, feel free to check out the GoSwitchgear cable lugs category page.

Standard Dimension Tables for Copper Lugs

For any panel builder or installer working across the UAE, having quick access to reliable data is a necessity, not a luxury. Using standardized copper lugs is non-negotiable for achieving a proper crimp that can handle the region's high ambient temperatures and humidity. This section serves as your quick-reference guide to dimensions for commonly used copper compression lugs.

Adherence to standards like DIN 46235 ensures every connection is mechanically robust and electrically sound. These tables allow you to instantly find the critical cable lug dimensions you need—from stud hole diameter to barrel length—for a wide range of cable sizes used in GCC projects.

Quick Reference for Copper Lug Dimensions

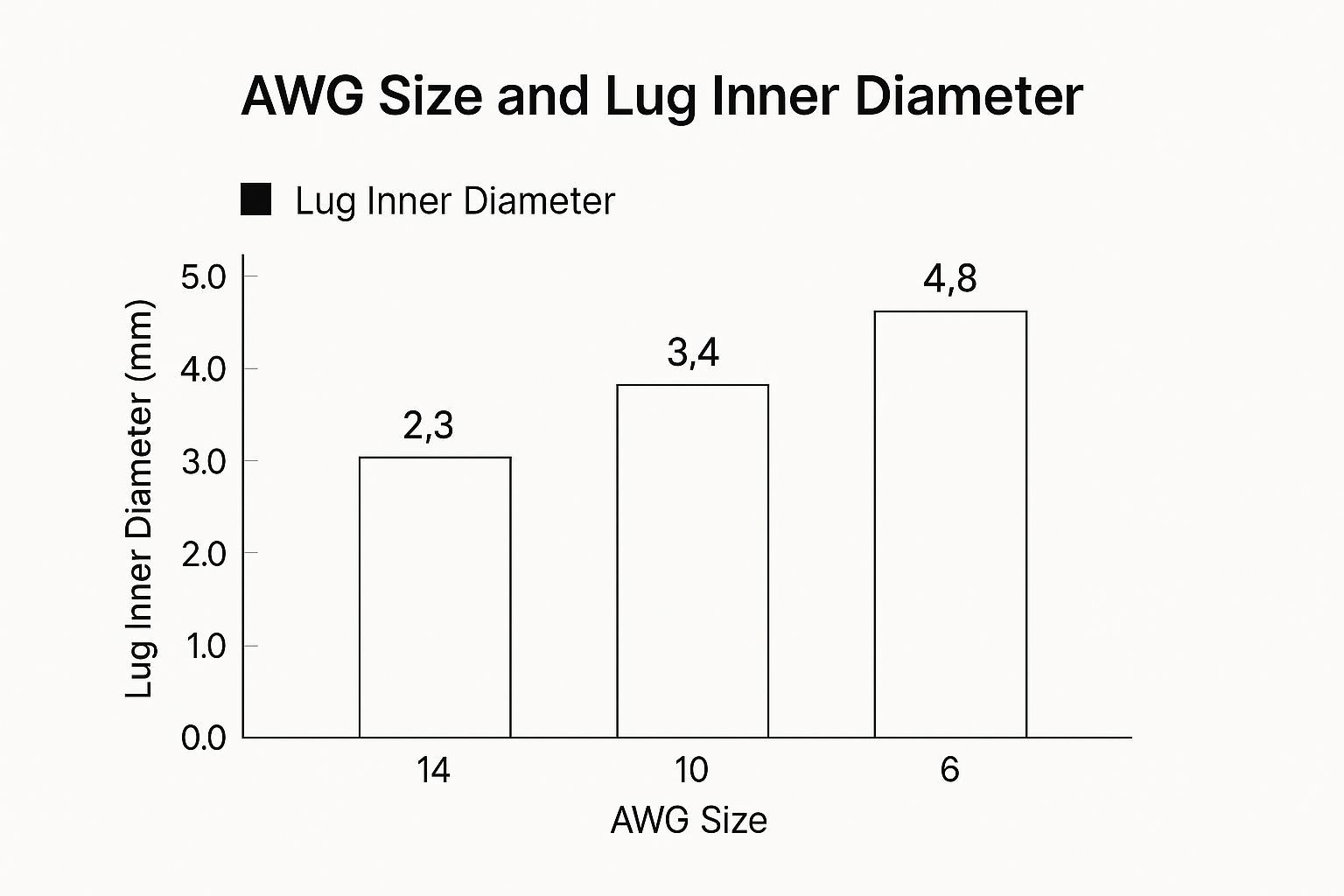

This visual guide demonstrates how common AWG cable sizes correspond with their required lug inner diameters, reinforcing the need for a precise fit to ensure a secure, long-lasting termination.

As shown, even a minor change in wire gauge necessitates a specific lug diameter to maintain a solid, reliable electrical connection vital for performance and safety.

Below is a detailed chart based on the DIN 46235 standard, which is widely adopted in the UAE and Saudi Arabia. We recommend bookmarking this page for quick verification during design or on-site installation.

Here's a quick lookup table with the essential specifications you'll need.

Standard Copper Cable Lug Dimensions (DIN 46235)

| Cable Size (mm²) | Stud Hole Diameter (mm) | Barrel Internal Diameter (mm) | Barrel Length (mm) | Overall Length (mm) |

|---|---|---|---|---|

| 16 | 8.4 | 5.8 | 10 | 33.5 |

| 25 | 10.5 | 7.2 | 12 | 41.0 |

| 50 | 13.0 | 9.8 | 16 | 54.0 |

| 95 | 13.0 | 13.5 | 20 | 69.0 |

| 120 | 17.0 | 15.2 | 22 | 80.5 |

| 185 | 17.0 | 18.5 | 28 | 98.0 |

| 240 | 21.0 | 21.0 | 32 | 114.0 |

| 300 | 21.0 | 23.5 | 36 | 126.0 |

| 400 | 21.0 | 26.5 | 40 | 143.0 |

This data is a practical tool to ensure every termination is precise, compliant, and built for longevity. Always double-check these values against the specific manufacturer's datasheet for the components you are using.

Dimensional Requirements for Aluminium and Bi-Metal Lugs

When working with aluminium conductors, standard copper lugs are unsuitable. The dimensional requirements are distinctly different. Aluminium lugs require a longer barrel and a larger outer diameter compared to their copper counterparts for the same cable size. This design is engineered to accommodate aluminium's lower conductivity and greater softness, ensuring a larger, more secure contact area for a solid, low-resistance crimp.

In places like Saudi Arabia and the UAE, getting this right is critical for both safety and performance. With infrastructure projects booming, both copper and aluminium lugs are widely used. According to one in-depth market report, manufacturers are focused on improving durability and corrosion resistance to meet the region's tough electrical codes and environmental challenges like heat and dust.

The Role of Bi-Metal Lugs

Whenever an aluminium cable must be connected to a copper busbar, the bi-metal lug is an essential piece of hardware. These are not simple connectors; they are specially engineered components designed to solve the dangerous problem of galvanic corrosion:

- An aluminium barrel, specifically designed to be crimped onto aluminium conductors.

- A copper palm, created for a safe and secure connection to copper busbars or terminals.

These two dissimilar metals are joined through a high-pressure friction welding process, creating a permanent, molecular bond. This is key to preventing galvanic corrosion—a destructive electro-chemical reaction that occurs when aluminium and copper are in direct contact, especially in the presence of moisture. In the humid climate of the GCC, this is a significant operational risk.

Using bi-metal lugs is not just a best practice; it is an absolute necessity for ensuring a safe, durable, and fully compliant termination between dissimilar metals.

How Regional Standards Influence Lug Sizing

In the GCC, electrical connections cannot be left to guesswork. The specific cable lug dimensions required are dictated by a combination of local and international standards aimed at ensuring total safety and compliance. These are not mere guidelines but mandatory requirements enforced by regional authorities.

Adhering to these standards is critical for both mechanical strength and electrical stability, especially given the region's harsh environmental conditions of high heat, humidity, and dust. For example, IEC 61238-1 is a key international standard for compression and mechanical connectors. It outlines strict testing criteria to ensure a lug can handle electrical and mechanical stresses over its lifespan without failure.

Local Utility Mandates

In addition to international benchmarks, local utilities like the Dubai Electricity and Water Authority (DEWA) have their own specific regulations for electrical terminations. These rules often impose stricter criteria to guarantee the long-term reliability and stability of the power grid.

Non-compliance is not a simple technical error. It can lead to project rejection, expensive rework, and serious safety risks. A connection failure due to improper sizing can cause power outages and catastrophic equipment damage.

This is precisely why sourcing components from a supplier like GoSwitchgear, who understands the local regulatory landscape, is crucial. Working with a knowledgeable partner ensures your project in Dubai achieves compliance and performs reliably.

Common Sizing Mistakes and How to Avoid Them

Even experienced professionals can make mistakes when selecting cable lug dimensions, leading to costly rework and severe safety hazards. Understanding these common pitfalls is the first step to ensuring every electrical termination is safe, compliant, and robust enough for conditions in the UAE.

One of the most frequent errors is selecting a lug with the wrong stud hole size for the terminal bolt. Another common issue is attempting to use a metric lug on an AWG cable without correct conversion, which guarantees a loose, high-resistance connection. Equally problematic is choosing a barrel length too short for a secure crimp, which can lead to mechanical failure.

Key Errors and Solutions

The best way to avoid these problems is to prioritize precision from the start. Here’s a look at common oversights and their practical solutions:

-

Mistake 1: Mismatched Stud Hole. Attempting to fit an M10 lug onto an M12 bolt.

- Solution: Always verify the terminal bolt or stud diameter with calipers before ordering. The lug's stud hole must provide a snug fit with minimal play.

-

Mistake 2: Incorrect Barrel Size. Crimping a 50mm² cable into a 70mm² lug.

- Solution: Never use an oversized lug. This creates high-resistance points that generate excessive heat. The cable’s cross-sectional area must exactly match the lug’s specification.

In markets like Saudi Arabia, regulations are incredibly strict, mandating exact dimensional properties for lugs to minimize electrical resistance and prevent overheating in high-load systems. This focus on accuracy is vital for building safer electrical networks, a trend explored in this market analysis. By helping clients navigate these challenges, we at GoSwitchgear demonstrate our commitment to project success and safety.

Your Partner for Compliant Connections in the GCC

As we've seen, getting your cable lug dimensions right is fundamental to the safety, reliability, and compliance of any electrical installation in the UAE and wider GCC. Understanding dimension charts, adhering to local standards, and avoiding common mistakes protects the integrity of your projects.

When you need expert support and a full range of high-quality, compliant electrical components, GoSwitchgear is your trusted partner. Our team is ready to provide technical assistance and quotes for your projects in Dubai, Abu Dhabi, and across the region. We supply the specialized electrical components that professionals depend on for critical applications. Contact us for project support in Dubai.

Your Questions on Cable Lug Dimensions Answered

Getting the small details right is what separates a professional job from a hazardous one. Here are common questions from engineers and technicians across the UAE about selecting the correct cable lug dimensions.

What Happens If I Use a Cable Lug with the Wrong Barrel Size?

Using a lug with a barrel that is too large for the cable will result in a poor crimp and an unreliable electrical connection. This can lead to high resistance, significant overheating, and a potential fire hazard. Conversely, if the barrel is too small, you cannot properly insert the cable. The rule is simple: always match the lug's specified cable size (e.g., 95mm²) to your cable's cross-sectional area to meet the stringent safety standards in the UAE and GCC.

How Do I Choose the Correct Stud Hole Dimension?

The stud hole dimension must precisely match the diameter of the bolt or stud on your termination point, whether it is a busbar, circuit breaker, or other terminal. For example, an M12 bolt requires a cable lug with a 12mm stud hole. A hole that is too large creates a loose connection and high resistance; too small, and it will not fit. Always verify the terminal bolt size before selecting your lug.

Are Dimension Standards Different for Copper and Aluminium Lugs?

Yes, the dimensions are quite different because the materials behave differently under compression. Aluminium lugs typically have longer barrels to create a larger crimping area, which is necessary for the softer aluminium wire to ensure a solid, reliable connection.

Critical Insight: When connecting an aluminium cable to a copper terminal, a bi-metal lug is essential. These lugs feature an aluminium barrel friction-welded to a copper palm, preventing galvanic corrosion—a significant risk in the GCC’s humid climate. Using the correct lug type is non-negotiable for a safe, long-lasting installation.

Why Is Barrel Length an Important Dimension?

The barrel length directly impacts the total surface area available for crimping, forming the foundation of the connection. A sufficient length allows the crimping tool to apply uniform pressure, creating a connection that is both mechanically strong and electrically sound. A barrel that is too short risks a weak crimp that could pull out under stress or create a high-resistance point, leading to dangerous heat buildup and eventual failure.

For a complete selection of high-quality, compliant electrical components for your projects in Dubai and Abu Dhabi, GoSwitchgear is your trusted partner. You can explore our extensive range of cable lugs and accessories right here: https://goswitchgear.com.

Leave a Reply