Selecting the Right ACB Circuit Breaker for UAE & GCC Projects

An Air Circuit Breaker (ACB) is the heavy-duty guardian of high-current electrical circuits, essential for safeguarding infrastructure across the UAE. Typically handling currents from 630A to 6300A, its primary function is to instantly interrupt power during an overload or short circuit, using ambient air to extinguish the powerful electrical arc and prevent catastrophic equipment damage.

Why Choosing the Right ACB is Critical for UAE Projects

For engineers, panel builders, and procurement teams in the UAE and wider GCC, selecting the right acb circuit breaker is fundamental to a safe, reliable power distribution system. The region's harsh climate—extreme heat, high humidity, and pervasive dust—places immense stress on electrical components, leading to premature failures, costly downtime, and significant safety risks if not properly specified.

An ACB in Dubai or Abu Dhabi must do more than manage electrical loads; it must withstand relentless environmental challenges. An incorrect choice can result in nuisance tripping, accelerated wear, and critical failure, jeopardizing assets in data centers, industrial plants, and commercial towers.

The Impact of Local Conditions on ACB Performance

The GCC environment directly influences an acb circuit breaker's performance and longevity. High ambient temperatures, often exceeding 45°C, necessitate careful temperature derating to ensure the breaker can handle its rated current without overheating. Furthermore, dust and humidity can degrade internal mechanisms and insulation, making robust construction and appropriate IP ratings essential for any project in the region.

This guide provides practical, locally relevant insights that go beyond standard datasheets. Understanding these nuances is key to building resilient electrical infrastructure. For any GCC project, consider:

- Temperature Derating: Ensure the ACB operates reliably at the high ambient temperatures common across the UAE and KSA.

- Enclosure and IP Rating: Select enclosures that effectively shield sensitive components from dust and moisture ingress.

- Compliance with Local Standards: Adherence to regulations from authorities like DEWA and ADDC is non-negotiable for safety and project approval.

Prioritizing a high-quality ACB from a trusted supplier like GoSwitchgear is an investment in your facility's long-term safety and operational continuity. Explore our full range of electrical protection equipment designed for the demands of the UAE market.

How an ACB Protects High-Current Systems

An acb circuit breaker functions as the ultimate guardian for high-power electrical systems. Under normal conditions, it allows current to flow unimpeded. However, the moment a dangerous overcurrent or short circuit occurs, it acts decisively to sever the connection and extinguish the resulting high-energy electrical arc.

This arc is a blast of intensely hot plasma capable of melting metal and causing explosions. The ACB’s primary mission is arc quenching—using the surrounding air to cool, stretch, and deionize the arc until it is safely extinguished. This entire process must be completed in milliseconds to protect valuable downstream equipment like transformers, generators, and large motors, making ACBs indispensable in industrial plants, data centers, and commercial towers across Dubai and Abu Dhabi.

The Mechanics of Arc Quenching

The process begins when the breaker’s trip unit detects a fault. Whether a thermal-magnetic unit or a modern microprocessor-based relay, it sends a signal to the operating mechanism, initiating a rapid mechanical sequence to isolate the faulty circuit.

At the heart of this operation are two sets of contacts:

- Main Contacts: Made of highly conductive copper alloy, these carry the full load current during normal operation with minimal resistance and heat.

- Arcing Contacts: Forged from a durable, arc-resistant silver-tungsten alloy, their sole purpose is to withstand the intense heat of the electrical arc.

When the breaker trips, the main contacts separate first, shunting the current to the arcing contacts. A split second later, the arcing contacts pull apart, drawing the arc between them. This two-step sequence protects the delicate main contacts from the destructive energy of the arc, significantly enhancing the breaker's lifespan and reliability.

Key Components in Action

Once the arc is drawn between the arcing contacts, the arc quenching system takes over. This system leverages electromechanical principles to manage immense energy safely.

The central component is the arc chute, a chamber containing a stack of insulated metal plates called arc splitters. As the arcing contacts separate, powerful electromagnetic forces and thermal effects drive the arc upward into this chute.

The arc chute is engineered to split the single, powerful arc into multiple smaller, cooler arcs as it jumps across the splitter plates. This action dramatically lengthens and cools the arc column, increasing its resistance until it is completely extinguished.

The entire sequence, from fault detection to arc extinction, is typically completed within 30 to 50 milliseconds. The speed and reliability of an acb circuit breaker make it a cornerstone of electrical safety in high-power applications.

This reliability is fueling significant market growth. The global air circuit breaker market, valued at USD 3.24 billion in 2019, is projected to reach USD 7.17 billion by 2032, driven by utility sector modernization in regions like the UAE. You can explore the full market analysis on Fortune Business Insights to see the trends. For engineers in the GCC, this underscores that quality manufacturing is a necessity, not a luxury.

Decoding ACB Specifications for the GCC Climate

For engineers and panel builders in the UAE and GCC, interpreting an air circuit breaker datasheet requires more than just reading numbers; it demands an understanding of which specifications are critical for our demanding climate. It’s about evaluating specs through the lens of a scorching Dubai summer or a high-demand industrial facility in Saudi Arabia.

Getting this right is the difference between a reliable, long-lasting installation and one prone to premature failure. Let's break down the key specifications you need to prioritize.

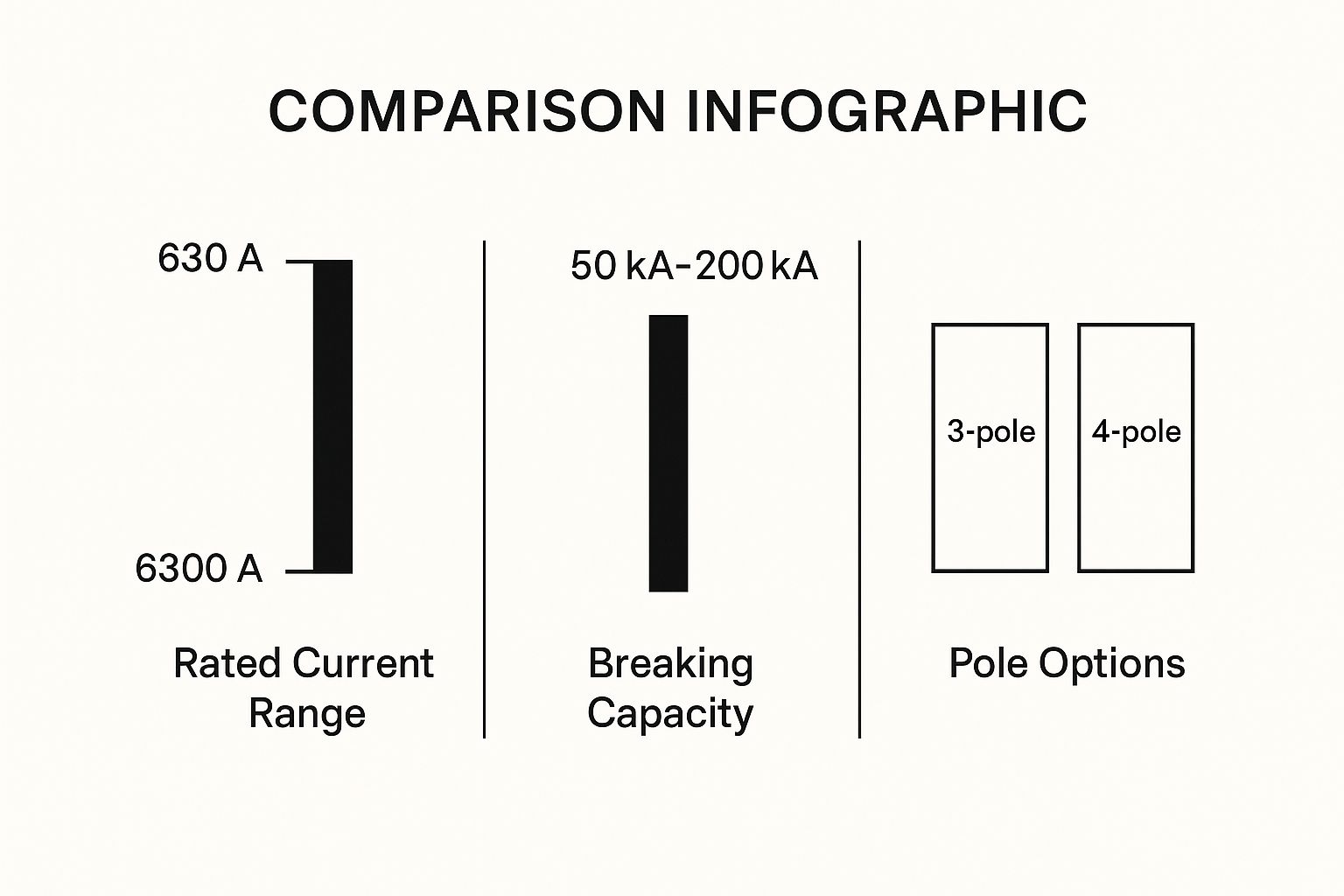

This image illustrates the versatility of ACBs, which protect circuits carrying anywhere from 630A up to a massive 6300A, making them suitable for applications ranging from commercial towers to large-scale industrial plants.

Rated Current and the Reality of Temperature Derating

The Rated Current (In) is the maximum current an ACB can continuously handle without overheating. However, in the GCC, this specification comes with a critical caveat: ambient heat.

Manufacturers typically rate their breakers at a standard 40°C. When installed in an environment with consistently higher ambient temperatures, the breaker's cooling efficiency is reduced. This requires a crucial adjustment known as temperature derating. For example, a breaker rated for 2000A at 40°C may only safely carry 1800A at 50°C. Ignoring this can lead to nuisance tripping or eventual equipment failure. Always consult the manufacturer's derating curves to select a breaker suited for the real-world conditions of your UAE project site.

Understanding Breaking Capacity: Icu vs. Ics

Breaking capacity is the most critical safety specification, indicating the maximum fault current the breaker can interrupt without catastrophic failure. Two ratings are key:

- Ultimate Breaking Capacity (Icu): The absolute maximum fault current the ACB can interrupt once. After such an event, the breaker may be damaged and requires inspection before reuse.

- Service Breaking Capacity (Ics): The maximum fault current the breaker can interrupt multiple times while remaining fully operational. It is often expressed as a percentage of Icu (e.g., 50%, 75%, or 100%).

For critical applications in the GCC—such as hospitals, data centers, or continuous industrial processes—specifying an ACB with an Ics that is 100% of its Icu is non-negotiable. This ensures maximum system uptime and reliability following a major fault.

The Brains of the Breaker: Trip Unit Technology

The trip unit is the intelligent core of the acb circuit breaker, responsible for detecting faults and initiating a trip. The technology within this unit significantly impacts the precision and flexibility of your system's protection.

ACB Trip Unit Technology Comparison

Choosing between a thermal-magnetic and a modern electronic trip unit can profoundly affect system reliability. Here’s a comparison to guide your decision for projects in the UAE and GCC.

| Feature | Thermal-Magnetic Trip Unit | Microprocessor (Electronic) Trip Unit |

|---|---|---|

| Adjustment | Limited, often with basic dials or fixed settings. | Highly configurable, allowing precise digital settings for current and time delays. |

| Protection | Provides basic overload (thermal) and short-circuit (magnetic) protection. | Offers advanced protection functions (LSI/LSIG), including long-time, short-time, instantaneous, and ground fault. |

| Accuracy | Less precise and can be affected by high ambient temperatures. | Extremely accurate and stable, completely unaffected by temperature swings—a huge plus for the UAE climate. |

| Communication | None. It's a standalone device. | Easily integrates with BMS or SCADA systems using protocols like Modbus for real-time data on energy use and faults. |

| Cost | Lower initial cost. | Higher upfront cost, but the superior protection, diagnostics, and control offer far greater long-term value. |

For the smart buildings and advanced industrial plants across Dubai and the GCC, microprocessor-based trip units are the standard. They deliver the precise, dependable protection and data communication essential for managing today's complex electrical components UAE systems. This level of control is fundamental for any modern energy management solution Dubai requires.

Choosing the Right ACB Type for Your Application

Selecting the right acb circuit breaker involves more than matching current ratings. The physical configuration and control method are critical decisions that impact performance, safety, and long-term operational efficiency. The two primary choices are Fixed vs. Draw-out mounting and Manual vs. Electrically Operated controls.

For engineers and panel builders in the UAE, making the correct choice is crucial for optimizing a system for its specific environment, whether it's an industrial facility in Sharjah or a mission-critical data center in Dubai.

Fixed vs. Draw-out ACBs: A Critical Decision

The choice between a fixed and a draw-out ACB is a trade-off between initial cost and long-term operational flexibility.

-

Fixed ACBs are bolted directly to the switchgear busbars. This permanent installation is less expensive upfront, making it a suitable choice for non-critical applications where maintenance downtime is acceptable, such as standard commercial buildings.

-

Draw-out ACBs are mounted on a movable chassis, allowing the breaker to be safely withdrawn ("racked out") from the live switchgear for maintenance or replacement. This design is the gold standard for applications where uptime is paramount.

In a Dubai data center, a major hospital, or any continuous process plant, a draw-out ACB is the only practical option. It allows a faulty breaker to be isolated and replaced in minutes instead of hours, saving a fortune in avoided downtime.

Manual vs. Electrically Operated Controls

The next decision is how the ACB circuit breaker will be operated. While manual operation is simple and reliable, the trend towards automation and smart buildings in the GCC makes electrically operated models increasingly common.

-

Manually Operated (MDO) ACBs require a technician to physically charge a spring mechanism and then use local push buttons or levers to open or close the breaker. It is a robust and cost-effective solution for applications that do not require remote control.

-

Electrically Operated (EDO) ACBs are equipped with a motor to automatically charge the spring mechanism. This enables the breaker to be opened and closed via remote electrical signals, making it an essential component for any modern, automated power management system.

For any facility in the UAE utilizing a Building Management System (BMS) or SCADA, EDO breakers are essential. They facilitate automated load shedding, remote intervention, and seamless integration into the comprehensive energy management solution Dubai projects require. Sizing the breaker correctly is equally important; our breaker size calculator can help you verify your calculations to ensure a perfect match for your application.

ACB Installation Best Practices for Peak Performance

A well-engineered acb circuit breaker only performs as well as its installation. For panel builders and technicians across the UAE and GCC, a precise installation is the final, critical step in guaranteeing safety and reliability. The region’s unique climate—with its intense heat, fine dust, and humidity—demands meticulous attention to detail that goes beyond standard procedures.

This is about avoiding common pitfalls and ensuring every ACB is commissioned for flawless, long-term performance.

Ensuring Adequate Panel Ventilation

An ACB generates significant heat during operation, a challenge compounded by the high ambient temperatures in the GCC. Without proper ventilation, components can degrade prematurely, leading to nuisance trips.

- Forced Ventilation: Install correctly sized, IP-rated panel fans to actively exhaust hot air. Ensure fan capacity is matched to the panel volume and the total heat load of all installed electrical components UAE.

- Strategic Louvres: Use filtered louvres to create a natural convective airflow—cool air in at the bottom, hot air out at the top. Regular filter cleaning is essential to prevent clogging from dust.

- Sufficient Clearance: Adhere strictly to the manufacturer’s specified minimum clearances around the ACB. This "breathing room" is critical for heat dissipation and prevents the formation of damaging hotspots.

Perfecting Busbar Connections with Correct Torque

A loose busbar connection in a high-current circuit creates high resistance and intense heat, posing a severe fire risk.

A calibrated torque wrench is a non-negotiable tool. Every bolt connecting busbars to the ACB terminals must be tightened to the manufacturer's exact torque specification. This ensures a secure, low-resistance connection that prevents dangerous overheating.

After torquing, apply a torque seal lacquer to each bolt. This provides a quick visual indicator during future maintenance checks if any connections have loosened due to vibration or thermal cycling.

Common Installation Mistakes to Avoid

- Improper Wiring of Auxiliary Contacts: Miswiring auxiliary (AUX) and trip alarm (SDE) contacts can lead to false alarms or, worse, no remote indication of a trip. Double-check wiring diagrams and use properly crimped ferrules for all control connections.

- Neglecting Enclosure IP Rating: Installing an ACB in an enclosure with an inadequate IP rating for a dusty or humid environment is a recipe for failure. Moisture and contaminants will ingress, causing corrosion and compromising insulation.

- Incorrect Trip Unit Settings: Modern microprocessor trip units offer great flexibility but must be configured correctly. Improperly set current or time-delay parameters can result in either inadequate protection or nuisance tripping.

By following these best practices, installers across Dubai, Abu Dhabi, and the GCC can ensure every acb circuit breaker is installed for maximum reliability and longevity.

A Practical Maintenance and Testing Schedule for ACBs

In the capital-intensive projects of the UAE, an ACB circuit breaker is a critical asset with an expected lifespan of 15 to 30 years. Achieving this requires a proactive maintenance strategy, which is essential for preventing unplanned downtime and ensuring compliance with local utility standards from authorities like DEWA or ADDC.

A structured maintenance plan preserves the integrity of the breaker’s mechanisms, contacts, and trip unit, ensuring it is ready to operate flawlessly when needed. This is especially vital in the GCC, where environmental factors can accelerate wear if neglected.

Routine Visual Inspections (Every 6 Months)

Regular visual checks are the first line of defense and can often be performed without de-energizing the equipment.

- Check for Dust and Debris: Dust accumulation can impair cooling and interfere with mechanical parts. Clean the ACB and its enclosure regularly.

- Look for Signs of Overheating: Inspect busbar connections for any discoloration or scorching, which indicates a loose connection requiring immediate attention.

- Inspect Physical Condition: Check the breaker's casing for any cracks or damage that could compromise its structural integrity or insulation.

Periodic Mechanical and Electrical Testing (Annually)

Annual in-depth testing is required to verify the operational health of the breaker. This involves a planned shutdown but is crucial for confirming that the ACB circuit breaker will perform under fault conditions.

A breaker that fails to trip is one of the most dangerous failure modes in an electrical system. Annual mechanical and electrical testing is non-negotiable for verifying the operational readiness of your most critical protective devices.

Key annual tests include:

- Mechanical Trip Test: Manually operate the push-to-trip button to confirm the mechanism moves freely without sticking or obstruction.

- Insulation Resistance Test: Use a megohmmeter to measure the insulation resistance between poles and from poles to ground. Low readings can indicate moisture ingress or insulation degradation.

- Contact Resistance Test: A micro-ohmmeter is used to measure the resistance of the main contacts when closed. An increase in resistance points to wear or contamination, which can cause overheating under load.

Consistent testing of all your protective devices is the foundation of a safe power system. For guidance on other key components, see our article on testing an RCD.

Common Questions About ACB Circuit Breakers

When sourcing an ACB circuit breaker for a project in the UAE, several key questions frequently arise. Getting clear answers is essential for making an informed decision that ensures facility safety and operational continuity.

One common question regards lifespan. A high-quality ACB, properly installed and maintained, is designed to last 15 to 30 years. However, the harsh GCC climate can accelerate wear, making a consistent maintenance schedule critical to achieving this service life.

What Causes an ACB to Trip Unnecessarily?

Nuisance tripping is a major operational disruption, and the cause is often external to the breaker itself.

Common culprits in the UAE include:

- High Ambient Temperatures: If temperature derating was not correctly applied during the design phase, the breaker may trip on a normal load due to excess heat.

- Incorrect Trip Unit Settings: Overly sensitive settings on a microprocessor trip unit can cause it to react to transient inrush currents or minor load fluctuations as if they were faults.

- Poor Connections: A loose busbar connection generates heat, which a thermal trip unit can misinterpret as an overload condition, leading to an unnecessary trip.

How Often Should ACBs Be Tested?

For critical facilities in Dubai and Abu Dhabi, a regular testing schedule is essential. While visual inspections should occur every six months, more comprehensive testing is needed to guarantee reliability.

As a best practice, conduct a full mechanical and electrical test on your ACB at least once every 12 to 24 months. This should include insulation resistance, contact resistance, and mechanical trip tests to verify that the breaker will perform reliably during a fault.

This proactive approach ensures reliability and compliance with local standards.

For expert support on selecting, installing, or maintaining the right acb circuit breaker for your projects in the UAE, trust the specialists at GoSwitchgear. Explore our extensive range of electrical components at https://goswitchgear.com.

Leave a Reply